Geology Reference

In-Depth Information

Behaviour of materials under

stress

The behaviour of rock material under-

going deformation is dependent on the

inter-relationship between the type of

rock (i.e. its

lithology

), embodying its

physical and chemical composition,

and the physical environment (tem-

perature and pressure) under which

the deformation takes place. It is dif-

ficult for us to imagine a piece of solid

rock being able easily to change shape

because it is outside our everyday expe-

rience, in the same way that we have

difficulty in imagining a solid object

consisting mostly of empty space (as the

physicists tell us!). However, laboratory

experiments help us here in applying

stress to material under artificially high

temperatures and pressures. Moreo-

ver, and critically, by conducting the

experiments for long periods of time,

more geologically realistic conditions

can be approximated, since much of

the deformation whose results we can

see in the real world has taken thou-

sands or millions of years to complete.

the nature of the strain quickly changes

thereafter if the stress is maintained.

In the case of most types of rock ma-

terial, when a large stress is applied, the

material will fracture after only a small

amount of elastic strain has occurred.

Most materials, including rock,

when subjected to a high enough

stress, exhibit permanent deforma-

tion - i.e. the strain does not disappear

when the stress is removed. This type

of deformation is called

plastic strain

and can be simulated by bending a

piece of plasticine or putty, or a thin

sheet of metal. In the case of the metal,

some elastic strain will take place

first, but eventually, with an increase

in the stress, or even by applying the

stress for long enough, plastic strain

will occur. Ideal plastic strain can be

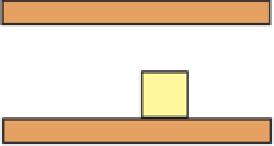

demonstrated using the analogy of an

object, such as a block of wood, being

pulled along a rough surface (Figure

4.10B). After an initial force is applied

to overcome the friction, steady plastic

strain is achieved by applying this force

4

26

27

spring

applied

force

applied

force

strain

strain

A

elastic strain

B

plastic strain

piston

failure

R

visco-elastic

strain

Q

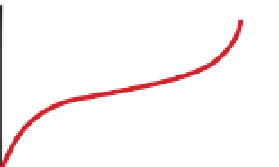

Elastic, plastic and viscous behaviour

The best way to understand how rock

material deforms is to first consider the

behaviour of familiar materials under

stress. Thus the behaviour of a piece of

rubber or a spring when extended is said

to be

elastic,

and in this type of strain

the material returns instantly to its ori-

ginal shape when the stress is removed.

Ideal elastic strain can be represented

by the amount by which a spring, say,

has been extended, and is proportional

to the force that is applied to the spring

(Figure 4.10A). Rock material can also

exhibit an element of elastic strain when

a stress is initially applied, although

strain

P

applied

force

strain

t

ime

C

viscous strain

D

creep

Figure 4.10

A.

Ideal elastic strain is represented by an applied force extending a spring; the amount

of strain equals the amount by which the spring has been extended; there is a steady (linear) increase

in strain with increase in stress and a steady increase in strain with time at constant stress.

B.

Ideal

plastic strain is represented by a block being pulled by an applied force along a rough surface,

opposed by sliding friction; the strain is represented by the distance travelled by the block; the

frictional resistance represents the yield stress; the strain increases without any increase in stress.

C.

Ideal viscous strain is represented by a piston, drawn through a cylinder by an applied force,

the strain being represented by the distance travelled by the piston; the force is opposed by the

resistance caused by the viscosity of the fluid in the cylinder; there is a steady (linear) increase of

strain-rate with stress and strain with time, at constant stress.

D.

Visco-elastic behaviour and creep:

strain-time graph showing a more realistic curve of variation of strain with time, known as a creep

curve; initial visco-elastic strain is followed at P by a period of steady-state strain increase (viscous)

followed in turn at Q by a period of accelerating strain ending in failure (R).

Search WWH ::

Custom Search