Environmental Engineering Reference

In-Depth Information

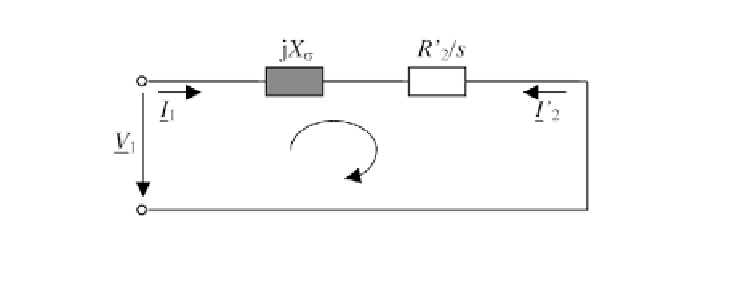

Figure 5.30

Simplified One-phase Equivalent Circuit for an

Asynchronous Machine

Power balance

High generator efficiencies are very important for wind power plants because

the majority of the mechanical power of the rotor blades connected to the

generator should be converted to electrical power and fed into the grid. The

ratio of the electrical power output

P

1

to the mechanical power input

P

2

defines the generator efficiency

. Asynchronous generators that are used in

large wind generators can reach efficiencies over 95 per cent. Although the

efficiencies are very good, the remaining losses are still very important. Losses

in the range of 5 per cent at generator powers of more than 1000 MW produce

large amounts of waste heat that must be removed. Figure 5.31 shows the

power balance and the different losses of an asynchronous generator.

The available mechanical input power

P

2

at the clutch is reduced by

friction losses

P

f

due to mechanical and air friction. The rotor windings have

ohmic losses, the so-called copper losses

P

Cu2

. The iron losses

P

Fe2

at the rotor

can be neglected. The reduced air-gap power

P

g

is transferred from the rotor

to the stator. It is given by:

η

(5.101)

The copper losses

P

Cu2

of the rotor winding occur at resistance

R

'

2

(see Figure

5.28). For three-phase windings these losses become:

(5.102)

Figure 5.31

Power Balance for an Asynchronous Generator