Environmental Engineering Reference

In-Depth Information

Number of rotor blades

Modern horizontal axis wind generators can have one, two or three rotor

blades. More than three blades are usually not used. The lower the number of

rotor blades, the less material is needed during manufacturing.

Single-bladed rotors

must have a counterweight on the opposite side of the

rotor. Single-bladed rotors do not have a smooth motion and therefore exhibit

a high material stress. Only very few prototypes with one rotor blade exist and

it is not expected that this will change soon.

The optimal power coefficient of three-bladed rotors is slightly above that

of two-bladed rotors. Three-bladed rotors have an optically smoother

operation and hence visually integrate better into the landscape. The

mechanical strain is also lower for three-bladed rotors. The advantages of

three-bladed rotors compensate for the disadvantage of the higher material

demand so that today mainly

three-bladed rotors

are built.

Wind speed ranges

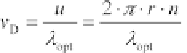

The design tip speed ratio depends closely on the number of rotor blades. The

maximum power coefficient of a three-bladed rotor is reached at a tip speed

ratio of between 7 and 8, whereas for two-bladed rotors the figure is 10 and

for a one-bladed rotor about 15. However, these values can vary depending on

the system design. The optimum tip speed ratio

λ

opt

also defines the

design

wind speed

along with the rotor radius

r

and the rotational speed of the rotor

n

in min

-1

.

(5.46)

For example, the optimum tip speed ratio of a three-blade wind turbine with a

rotor radius of

r

= 22 m and a rotational speed of

n

= 28 min

-1

= 0.467

s

-1

is

λ

opt

= 7.5, and therefore the design wind speed is

v

D

= 8.6 m/s. The

wind turbine has its maximum efficiency at this wind speed. The design wind

speed is very important for wind turbines with constant speed. Systems with

variable speed can obtain the optimum efficiency at other wind speeds also. In

this case, the design wind speed

range

should replace the design wind speed.

At very low wind speeds the operation of the wind turbine makes little

sense. No power or only a very little power can be taken from the wind and

the wind generator can even become a power consumer. Therefore, the rotor

brake should stop the wind turbine below a predefined starting wind speed, or

cut-in wind speed v

cut-in

.

The design wind speed

v

D

was explained above; the rated or

nominal wind

speed v

N

of a wind turbine is usually different. At the nominal wind speed, the

wind turbine generates the rated power. The nominal wind speed is usually

higher than the design wind speed. Above the nominal wind speed, the power

of the wind turbine must be limited. If the wind speed becomes too high, the

wind power plant can be overloaded and damaged. Therefore, wind turbines

cut out at high wind speeds,

v

cut-out

: the rotor brakes stop the wind turbine