Environmental Engineering Reference

In-Depth Information

Table 3.5

Absorption, Transmission and Reflection Factors for IR Glass

In

2

O

3

and ZnO

2

Compared with Ordinary Window Glass

Visible

Infrared

α

ε

τ

ρ

α

ε

τ

ρ

Material

=

=

Window glass

0.02

0.97

0.01

0.94

0

0.06

In

2

O

3

0.10

0.85

0.05

0.15

0

0.85

ZnO

2

0.20

0.79

0.01

0.16

0

0.84

Source:

Kleemann and Meliß, 1993

The material for the

rear heat insulation

must be temperature resistant and

highly insulating. Suitable materials are polyurethane foam or mineral fibre

slabs. The insulation and all other materials should not contain binding agents

that may evaporate at higher temperatures because these could condense on

the front glass pane and reduce the incoming solar radiation.

The collector can reach stagnation temperatures of about 200°C. All

materials used must therefore resist these temperatures. As a result, the

absorber is usually made of metal such as copper, steel or aluminium. Various

absorber designs are used as shown in Figure 3.9. Absorbers with soldered or

forced copper pipe are the most commonly used today. Aluminium is now little

used as absorber material, since it is not corrosion-resistant and its production

needs much more energy input than other materials.

It is well known that black materials absorb sunlight very well and warm

up to higher temperatures. However, metallic materials do not naturally have

black surfaces and must therefore be coated. Black lacquer is one option.

Temperature-resistant lacquer serves its purpose but there are more advanced

materials available for

absorber coating

. If a black surface heats up, it re-emits

part of the absorbed heat energy as heat radiation. This can be noticed with

electrical hotplates for cooking. The heat radiation can be felt on the skin

without touching the hotplate. A black lacquered absorber exhibits the same

effect. It transfers only a part of the absorbed heat to the water flowing

through; the rest of the heat is undesirably emitted as heat radiation to the

environment.

So-called

selective coatings

absorb the sunlight nearly as well as black

lacquered surfaces but re-emit a significantly smaller amount of heat radiation.

Materials used for these advanced coatings include black chrome, black nickel

or TiNOX. However, they need more complicated coating processes than black

lacquer and so incur higher costs.

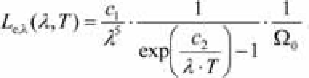

Figure 3.10 shows the different material behaviours. It is necessary to look

at the spectrum of the heat radiation to describe the principle of selectively

coated absorbers. The

radiance L

e

depends on the absolute temperature

T

and

wavelength

λ

and is given according to Planck by:

(3.10)