Biomedical Engineering Reference

In-Depth Information

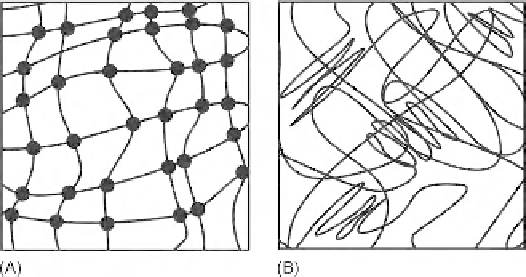

Figure 11.10

Schematic representation of (A) chemically crosslinked hydrogel and

(B) physical hydrogel with multiple interaction zones.

polymers may biodegrade simply because of their ability to absorb water and dis-

solve. Polymers composed of proteins or polysaccharides can undergo enzymatic

hydrolysis. The presence of a specific enzyme at some site of the constituent polymer

can be exploited to develop hydrogels for site-specific delivery

[301]

.

Biodegradable hydrogels offer advantages for incorporation of water-soluble

P/P as they are composed largely of water, and there is no need to remove polymer

residues from the implant site after the drug is exhausted. Biodegradable hydrogels

provide an alternative mechanism of drug release from the polymer matrix, such as

controlled and sustained release for protein formulations that also have tissue engi-

neering potentials

[302-304]

. Another advantage of the hydrogel as a protein and

peptide delivery system is that it may avoid exposure to organic solvents or high

temperatures, unlike the synthesis of some hydrophobic polymers, so chances of pro-

tein denaturation are reduced with such systems. The entry of sustained-release con-

cept into the tissue engineering field is now evident with incorporation of proteins

(usually growth factors, e.g., for bone regeneration)

[305-309]

into various scaffolds.

Interestingly, to control the time of release and the spatial distribution of incorpo-

rated protein molecules inside the scaffolds, an approach commonly applied is to first

encapsulate proteins into polymeric microparticles that are then embedded inside the

scaffold

[15,310-311]

. High protein loading and encapsulation efficiency and ease

in upscaling are some more attractive features of hydrogel as delivery system for P/P

drugs. Various stimuli for the delivery of proteins and peptides from hydrogels, such

as pH, ionic strength, chemical species, enzyme substrate, mechanical, thermal, elec-

trical, and ultrasound stimuli, have also been studied and are investigated for suitable

and targeted P/P release

[312-314]

.

Hydrophilic polymers can be transformed into a microparticulate system using

a simple water-in-oil emulsification procedure

[68]

. The particles may be stabilized

by a crosslinking procedure or by coating the particles with a hydrophobic polymer.

Release from these particles is controlled by diffusion through the pores that are

formed by degradation or swelling of the matrix. The various developments in the

area of hydrogels for proteins and peptides delivery have been listed in

Table 11.9

.

Search WWH ::

Custom Search