Information Technology Reference

In-Depth Information

are of three types: quill, power, and CNC. Quill units are used for light drilling and drilling-

related operations as they also provide the spindle with a linear feed motion necessary for

penetration of the cutting tool into the workpiece. Both the linear and the rotational motions

necessary for performing operation are provided simultaneously. Power units are used for

drilling, drilling related, and milling operations where large cutting forces exist. Unlike quill

units, power units lack the linear feed motion due to presence of significantly larger cutting

forces that may cause deflection in the rotating spindle. Consequently, these units are mounted

on the sliding units providing them with necessary linear feed motion. Figure 2 shows quill

and power units together with tool holders and cutting tools.

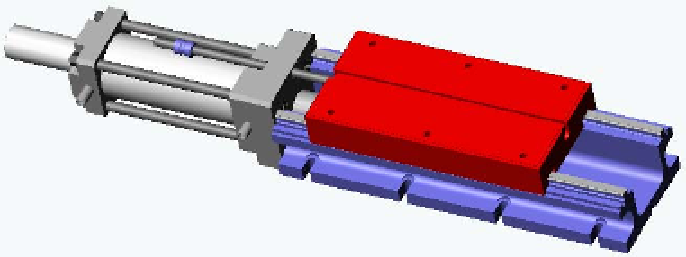

Fig. 2. A pneumatic sliding unit with mechanical course adjustment

(Photo: Tolouei-Rad and Zolfaghari, 2009)

Sliding units may carry machining units and provide necessary feed motion of the tool by

means of hydraulic/pneumatic actuators, or servomotors. Adjusting the course of motion is

provided by use of micro-switches or mechanical limits. Figure 3 shows a pneumatic sliding

unit with a mechanical course adjustment device. The sliding plate that carries the

machining unit is fastened to the connecting rod of the piston, and therefore, is capable of

moving back and forth on the base. Depending on the nature of machining operation and

cutting tool motion requirements, machining units can be mounted on the sliding unit such

that spindle axis is either along or perpendicular to the sliding direction.

Fig. 3. A pneumatic sliding unit with mechanical course adjustment