Environmental Engineering Reference

In-Depth Information

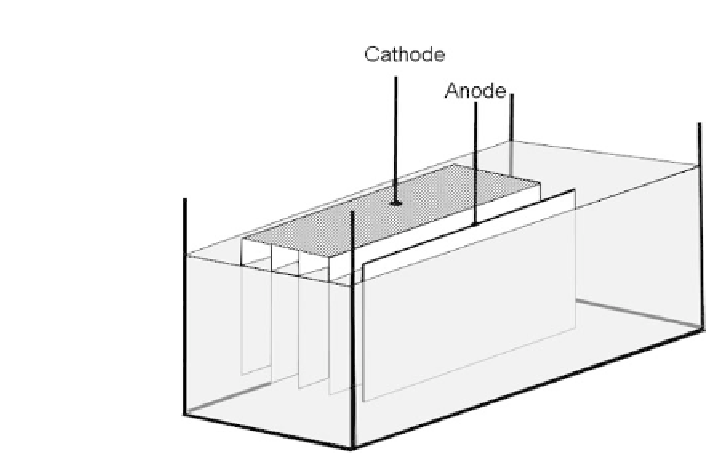

Figure 3.2

Electrodeposition is suitable for the processing of batches of

large-area devices through multi-plate cathodic deposition. See also Colour

Insert.

be prepared using this technique. The production of 0.9 m

2

solar panels by BP Solar using electrodeposited CdTe achieving

e

ciencies greater than 10% has proved the manufacturability of

this technology. Recent accelerated work on electrodeposited solar

energy materials and devices in many parts of the world [11-13]

shows the recognition ofthe strengths ofthis simple technique.

3.3.2

Self-Purification and Built-in Hydrogen Passivation

In the development of electronic materials and devices, impurity

control is a critical issue. The first step is to minimise the impurity

sources present in and around the electrolyte. The solvent used in

the electrolyte should be a high-purity medium, and in the case of

aqueous solutions, double-distilled water or de-ionised water fulfils

therequirement.Inmanysituations,theelectrolytesareacidic,with

pH values in the range 2-4, and under these conditions, silicon and

sodium ions leach into the electrolyte from glass vessels used for

the electrolytic bath [14]. This can be easily eliminated by using

Teflonware instead ofglassware inthe electrolytic bath.