Hardware Reference

In-Depth Information

Tabl e 2. 1

Bridging defects

Guaranteed range .K/

Total number of bridges

Rb 0:5

258 (64.5%)

Rb 1

379 (94.8%)

Rb 5

394 (98.5%)

Rb 10

397 (99.3%)

Rb 20

400 (100%)

Guaranteed range

.

K

/

Total number of bridges

Rb 0:5

14 (3.5%)

Rb 1

12 (3.0%)

Rb 5

4 (1.0%)

Rb 10

2 (0.5%)

Rb 20

0(0%)

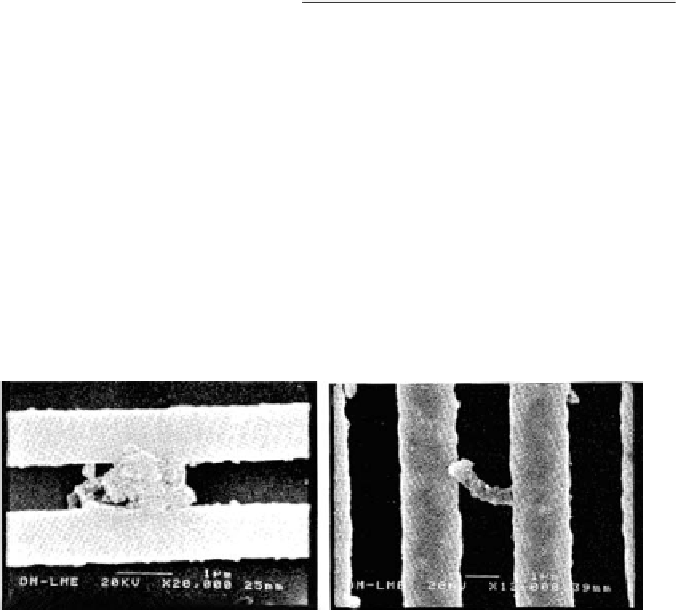

Fig. 2.7

(

a

) Low resistive and (

b

) high resistive bridging defect

(

Rodrıguez-Monta nes et al.

1996

)

side, 3.5% of the bridges have a resistance above 500 . The maximum resistance

value was found to be around 20 k. Two pictures of a low resistive and a high

2.3

Detectability of Bridging Defects

As the quality demands increase, the effectiveness of test generation without any

defect consideration becomes questionable. High quality test generation requires a

better knowledge of defect behaviour. As a matter of fact, the analysis of defect be-

haviour is a quite difficult task. One of the main difficulties comes from the presence

in the defect of random value parameters such as the bridging resistance preventing

any prediction of the defect behaviour. The mechanisms of defect appearance are

obviously not controlled, resulting in electrical situations with unknown parame-

ters. The question is how to predict the voltage created by a bridge when the value

of the bridge resistance is not known a priori. The classical assumptions such as