Biomedical Engineering Reference

In-Depth Information

RISK ANALYSIS

1

2

3

Characteristic

Life Cycle Phase

Design, Manufacture, and Supply

Comment

Failure/Hazard

Effect

Hazard Relevance

= relevant

Root Cause(s)

4

5

6

7

8

9

10

11

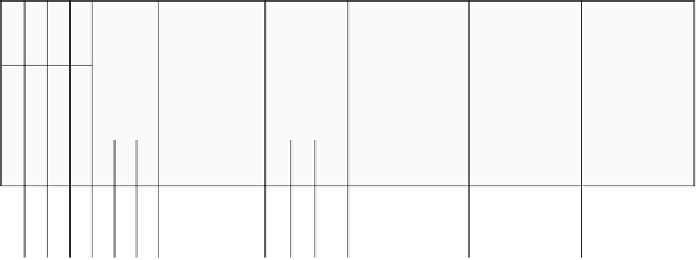

Figure 9.1

Example risk analysis pro forma.

failure modes for a particular hazard; a single failure mode is entered into box 2. Each failure

mode/hazard will have a particular effect (note this is related to the patient, the end-user, or the

surrounding environment - box 5); this is explained in box 3. Now you have to identify the root

cause, or the root causes (box 4); it is very likely that each hazard/failure will have a number of

potential root causes. This is where our Ishikawa diagrams and our reliability calculations come

into force (Chapter 7).

Table 9.3

is a summary of the potential root causes as stated in ISO 14971. It is by no means

comprehensive but it gives you some ideas. As stated earlier, and continuously throughout

this text, a comprehensive PDS and design procedure will have anticipated all of these root

causes and designed them out!

For each cause we now assess the risk (box 6). Similar to what we examined in FMEA,

we determine a level of severity (S) and a likelihood of occurrence (L). But unlike FMEA

we DO NOT include delectability. Our assessment of RISK level (RPN) is

RPNSL

(9.1)

As with FMEA, we need guidelines on setting values of L and S. ISO 14971 suggests values but

also lets the company allocate their own appropriate levels; those in

Table 9.4

are commonplace.

Note that severity is based on potential for injury; company embarrassment is no longer a

consideration!

We now have to assess if the risk is acceptable or not.

Table 9.5

illustrates a typical risk evaluation

table. ISO 14971 allows you to devise your own threshold values, but it is very common to have

three zones: a low risk zone (no controls required); a medium risk zone (controls should be

examined); and a high risk zone (controls need to be implemented to reduce risk).

Search WWH ::

Custom Search