Biomedical Engineering Reference

In-Depth Information

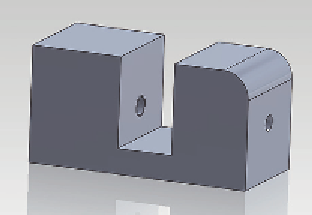

6 H5 THRO

M8 blind hole

Figure 8.20

Ill-conceived design with no thought for manufacturing.

model that works “on paper” but completely forgot how it is going to be made (not just made

but made efficiently and cheaply). How is the M8 hole to be machined? There is a piece of

metalwork in the way - and the 6 mm hole is not big enough to allow a tap to be introduced.

Hence the designer has not thought about how it is going to be made!

Now consider a component with several holes, all of different diameters. Are these

diameters really necessary? Can we reduce the number of diameters? “Why?” I hear you

ask. Because the operator (or the machine) has to change the drill for each hole, and this

wastes time and hence wastes money. Also the manufacturer has to stock all of the drills,

many times over. All of this adds to unnecessary cost that will drive up the cost of your

device. Do not forget, it is not only the material used in your actual component, you also

have to add how much scrap your produce: you pay for the scrap! As shown in

Figure 8.21

this can be very costly!

Once again, consider the component illustrated in

Figure 8.20

. Does the hole have to be such

a tight tolerance? Can its tolerance be lowered so that a more simple process can be used? A

general procedure to process these questions is illustrated by

Figure 8.22

.

How is the machine operator expected to hold the device? You may think this silly, but if you

are having your components coated then where they are held becomes important as that point

will have no coating!

You will notice that this is where communication with your potential manufacturer comes into

play. Failure to perform DFM is the main reason for most design failures at the prototype stage;

it is where you get the embarrassing phone call “and how do you expect us to make this?” If you

bring manufacturing expertise into play as soon as possible then DFM becomes very easy indeed.

Some questions to consider, in addition to those in

Table 8.7

, are:

l

How is it likely to be made (what process)?

l

Are there too many variations of design features?

Search WWH ::

Custom Search