Biomedical Engineering Reference

In-Depth Information

The next question is: What do we do with this data? There are two interpretations. The first

concerns minimizing manufacturing errors. If you want to make your quality control more

robust then you must examine the outliers and see how to best control them or remove them

from the design. Clearly, if you are able, then these should be tightly toleranced. All others

have a small effect but your level of control need not be so high, if at all.

The second way of looking at the data is if you are trying to maximize the effect; now the

data tells you which parameters are the most important and hence which you should vary to

improve your outcome.

As you can see, 2

k

experimentation (or “design of experiments”) is an extremely powerful

tool. I have only presented the most basic of introductions; if you wish to understand more

then a good text is

Montgomery (2001)

. If you would like to play with this method conduct

a web search for “Taguchi Paper Helicopter” and you will find links to a great example of

“design of experiments.”

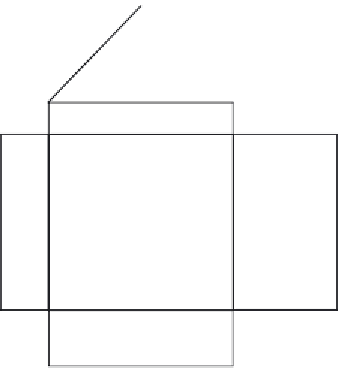

7.4 House of Quality

We have appreciated the importance of customer/end-user input into design. But how do we

know that we have really taken them into account, and how can we use this knowledge to

differentiate ourselves in the marketplace? One of the most valuable tools is the House of

Quality (or HoQ as I shall now term it).

Figure 7.7

is a schematic of an HoQ structure.

The HoQ is split into zones. The first “room” is customer requirements; in this room the

individual requirements, as detailed by your customers and end-users are tabulated as

Cross-talk

Technical specs

Correlation

Targets

Figure 7.7

Typical House of Quality structure.

Search WWH ::

Custom Search