Graphics Reference

In-Depth Information

However, analyzing STL files for errors and

buildability has never been easier. Each of

the following software packages has

strengths that when used together, can

make it easy to edit and print great looking

scans.

Get a Handle On It!

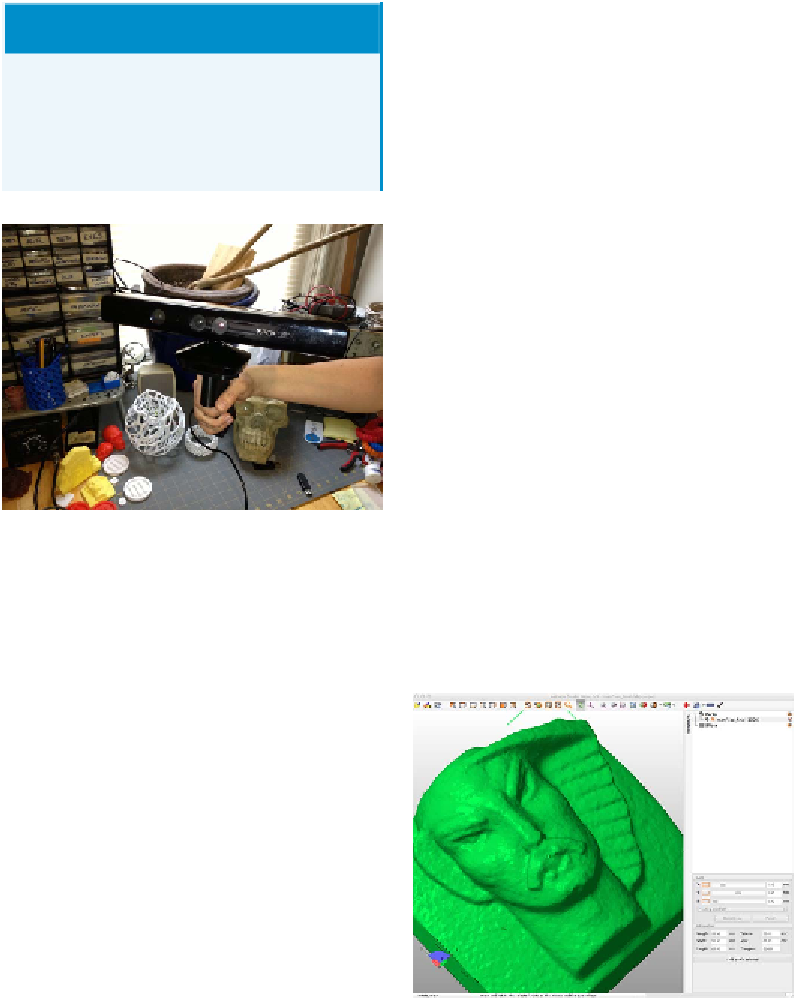

If you are scanning other people or things, a

mount (

or such as this

) can come in handy (see

Figure 6-10

).

Tony Buser created the seminal vid-

eo tutorial on cleaning and repair-

ing 3D scans that deeply informed

this chapter

(

you can watch here

).

netfabb

netfabb (

Figure 6-11

) enables you to view

and edit meshes and provides excellent re-

pair and analysis capabilities for your STL

files. netfabb makes it easy to slice off bits of

jagged scans and quickly repair those scans.

In most cases, you will want to slice off the

bottom of your model to create a flat surface

against the build platform.

Figure 6-10.

Kinect on a handle

Cleaning and Repairing

Scans for 3D Printing

While it is becoming easier to create high-

quality scans, creating valid input files is

sometimes difficult. Before you can print

your 3D scans, you need to clean up, edit, and

repair the files to make them printable.

The most common problems with 3D scans

are:

•

Holes

•

Disconnected parts

•

“Junk” from the environment around the

model or used to map the object in

space that is not part of the model

•

Open objects with faces that are not

closed

Figure 6-11.

123D Catch scan of a stone face, shown

in netfabb