Graphics Reference

In-Depth Information

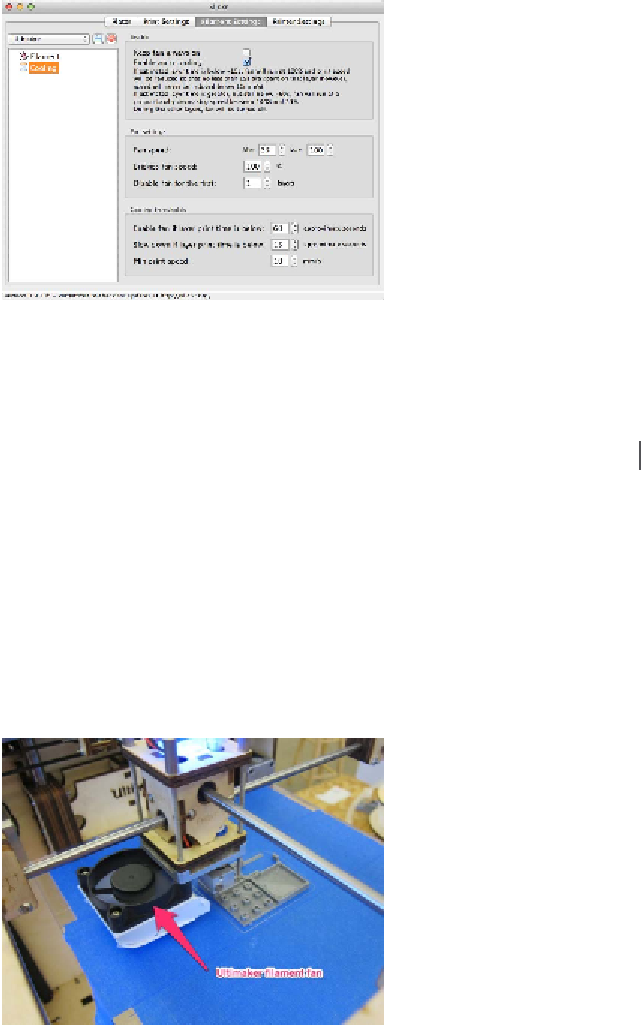

I like to disable the fan for the first layer to

keep the plastic as gooey and liquid as pos-

sible, to keep it stuck to the bed (this is es-

pecially popular with PLA printing). You can

also check a box to keep the fan on at all

times, from print start to end.

The cooling thresholds give you more ad-

vanced control over when the fan starts. In

general, layers with shorter print times (such

as the tip of a cone) are more difficult for the

printer to complete successfully, and there-

fore benefit most from additional airflow.

Figure 5-20.

Cooling settings

The thresholds to set for decreased printing

speed will come with time and lots of exper-

imentation, but I think these are a good start-

ing point:

As you adjust the following settings, refer

back to the description under the enable au-

to cooling box to see how your edits will

change the intelligent cooling activity of the

machine during printing.

Enable fan if layer print time is below

60 seconds

Slow down if layer print time is below

15 seconds

Fan speed is a percentage and is really up to

you. Do a few prints with cooling enabled

and increase the minimum fan speed if you

notice that your plastic is drooping or exces-

sively sticking to the nozzle. Bridges fan

speed is how fast the fan will turn during

bridging—keep this high to promote cool-

ing and minimize drooping.

Min print speed

10 mm/sec

You can set the minimum print speed fairly

low; this will result in a great variation in print

speed during more challenging prints.

You may find that separate cooling thresh-

olds are necessary for different parts, so cre-

ating a different slicing profile for each may

be the quickest solution—for example, one

for objects with lots of narrow columns, and

one for hollow objects, one for busts (where

detail is important).

Step 4: Printer Settings

Now we can move onto the Printer Settings

tab (

Figure 5-22

). Before we start with gen-

eral settings, break out the ruler. Measure the

usable length and width of your print area,

and enter the results into the bed size boxes.

The print center should be half of the bed

length and width, so that the print starts at

the exact center of the build platform.

Figure 5-21.

The Ultimaker fan