Graphics Reference

In-Depth Information

For PLA, an extruder temperature of 185 is

probably as low as you want to go (this Ulti-

maker profile is set for PLA printing). For ABS,

I'd recommend starting at 220.

If you have a heated bed, use it at whatever

temperature you feel comfortable with,

since anything will help. For PLA, 60 is prob-

ably a good place to start, and 110 is good

for ABS (although if your bed takes forever to

get that hot, dial it down so you won't have

to wait hours for a print to start).

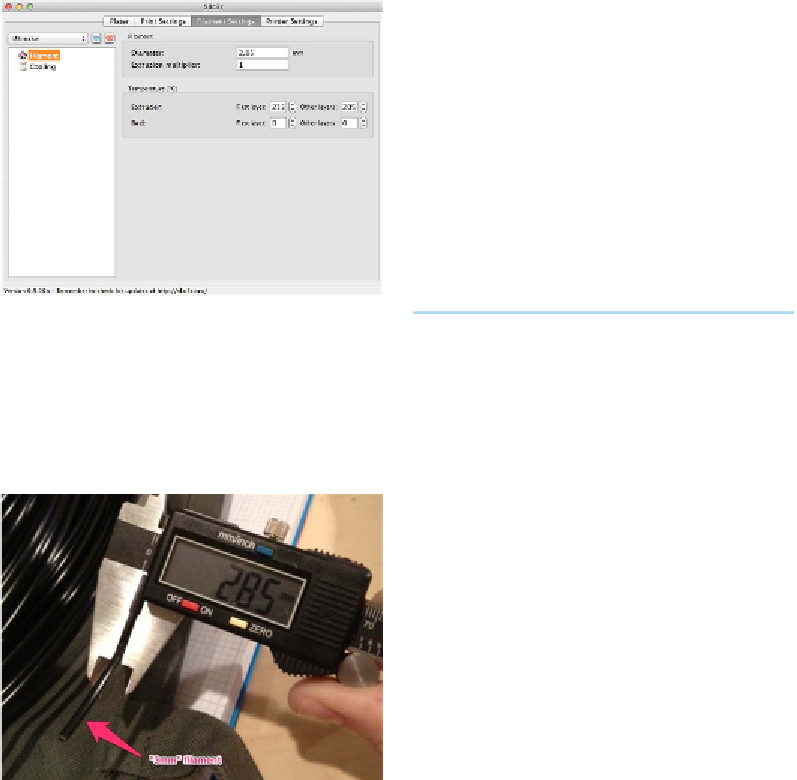

Figure 5-18.

Filament settings

If you don't have a heated bed,

keep the bed temperature at 0. If it

isn't at 0, the print will never start.

So, take a caliper or micrometer to your fila-

ment at a few different positions, and aver-

age your readings (

Figure 5-19

). Input the

average into Slic3r.

Cooling

Next up is the cooling settings page

(

Figure 5-20

). Start with the fan settings. If

your machine doesn't have a fan directed at

the extruder or build platform (

Figure 5-21

),

you can skip this step. If you have a fan, check

“Enable auto cooling” and read the descrip-

tion that pops up when you hover your

mouse over it—this setting will intelligently

cool only when needed, and keep the fan off

at all other times.

Figure 5-19.

Caliper measurement

The extrusion multiplier will simply alter the

value you just entered into the diameter box.

Unless you have a specific reason to do so,

leave this at 1.

Extruder and bed temperature are also very

important. You can specify a different tem-

perature for the first layer. If anything, run

your extruder hotter than usual to start, to

promote extra gooeyness and stickiness.