Graphics Reference

In-Depth Information

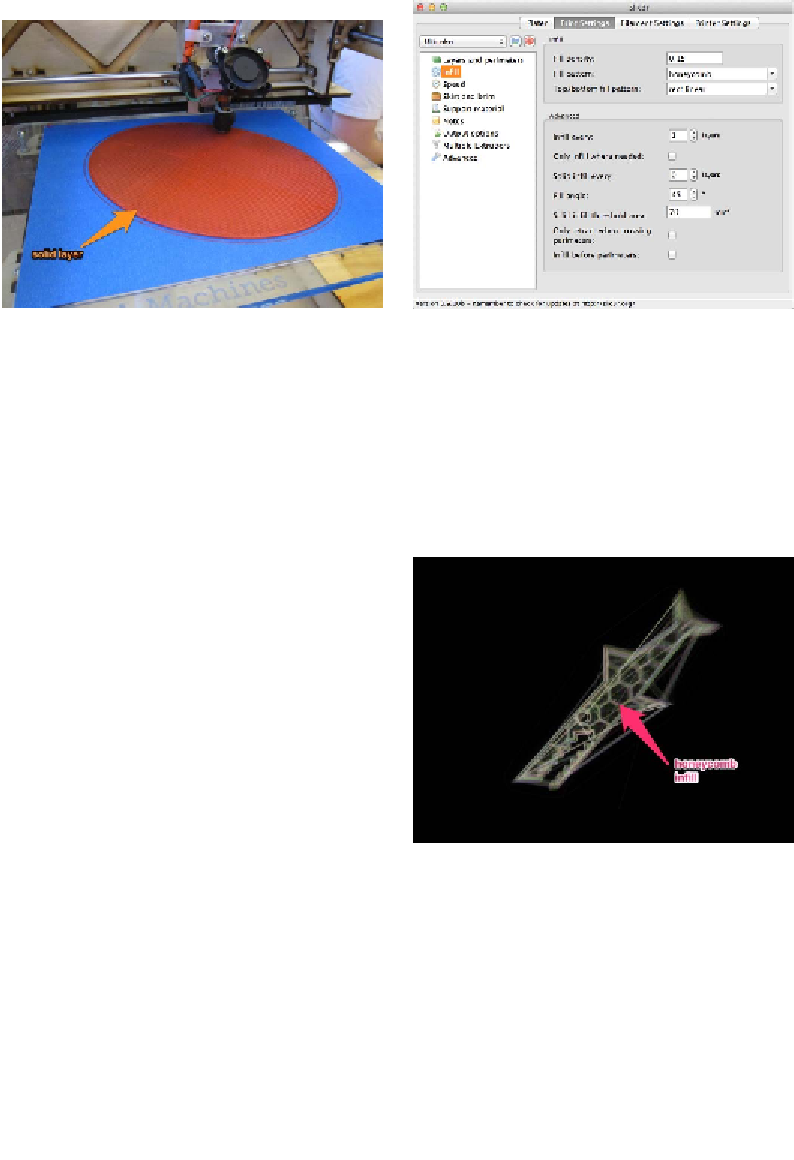

Figure 5-6.

Solid layers

Figure 5-7.

Setting fill options

Keep in mind that if you're printing a very

large part, each solid layer will take up a good

chunk of time, so dial those values down if

you value print time over part strength.

The fill pattern (

Figure 5-8

) is the path that

the extruder takes when doing the infill.

These don't have a huge impact on the struc-

tural stability of the part. The “Top/bottom

fill pattern” is the pattern used on the top and

bottom solid layers.

Infill

Fill density (

Figure 5-7

) is the percentage of

each layer that will be filled in with plastic

(0.2 = 20%). You shouldn't have to go above

60% for any reason, unless you want a really

dense part. A 20% fill is just fine for your ev-

eryday prints, but adjust at will and play with

the parts once they're complete to feel the

difference in structural stability.

A density of 0 will only print the perimeter(s)

of your part, so it will be completely hollow.

Figure 5-8.

The fill pattern inside an object

The advanced settings give you even more

control over the infill, although I don't think

I've ever touched them. “Infill every 2 layers”

will alternate between layers of filled (with

the fill density you chose) and hollow. “Infill

every 3 layers” will have two hollow layers