Graphics Reference

In-Depth Information

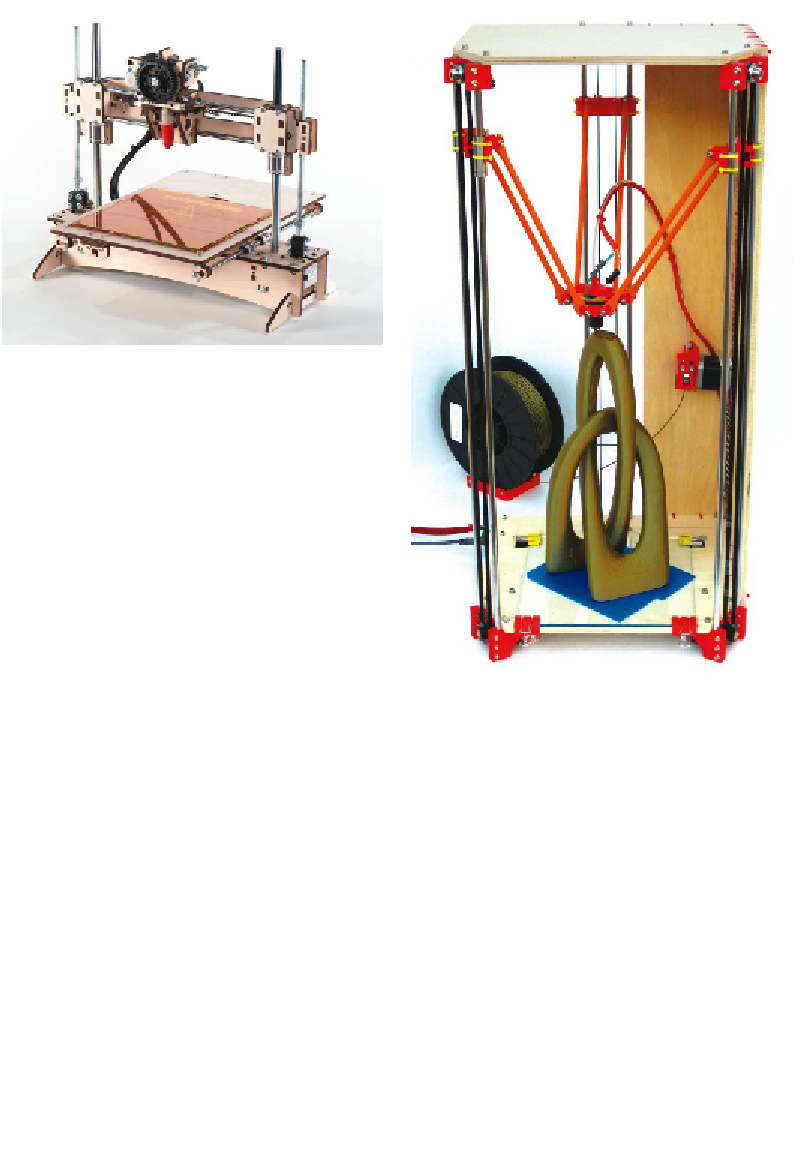

Figure 1-3.

A Printrbot

Deltabot

Industrial pick-and-place robots typical-

ly use this design. A deltabot has three

control rods connected to the toolhead,

and these rods can be moved to control

the position of the head. Recently, Jo-

hann Rocholl adapted this technology

to 3D printing and created the Rostock

(

Figure 1-4

). Hard to explain, it looks like

an alien probe is printing your favorite

model.

The Rostock printers (so far) use a Bow-

den setup to separate the hot-end from

the extruder, allowing for very quick and

precise head positioning with relative

mechanical simplicity. The downside is

increased complexity in the driver; the

hot-end positioning is not a linear set of

steps because of the non-linearity of the

motion between the vertical axis and

the planar positioning of the hot-end.

Figure 1-4.

The Rostock

3D Printer Parts

Print bed

This is the bed upon which the printed

part rests during production. Bed tem-

peratures can be ambient or heated. A

non-heated bed is often covered in

painter's tape, as seen in the Ultimaker

(

Figure 1-1

), to which the printed mate-

rial adheres. Heated beds, as seen in the

Printrbot (

Figure 1-3

), keep the part

warm during the print and prevent

warping. Depending on the material, a

heated bed will maintain a temperature

from 40°C to 110°C throughout the print.