Graphics Reference

In-Depth Information

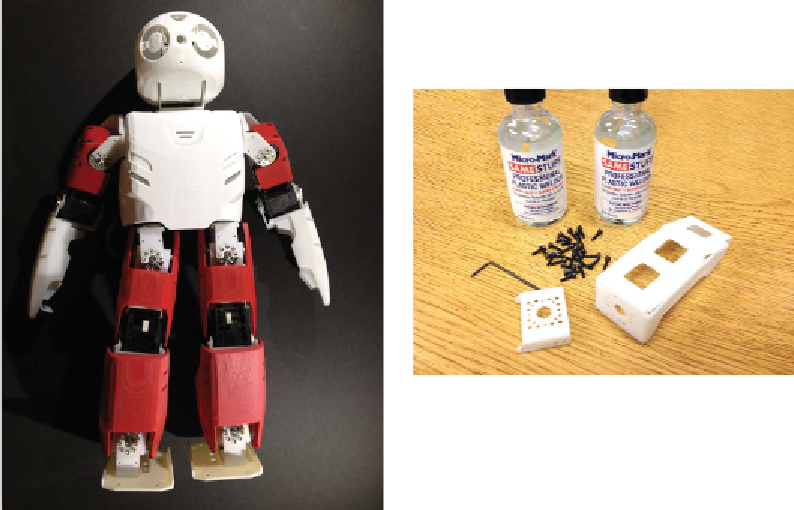

Today, my DARwIn-OP clone (

Figure 19-2

) is

fully assembled, and I've spent about $6,100,

not counting the costs of the 3D printers I

used. That's still a lot—but it's almost half off

the factory price.

world—fast, high torque, and very high

resolution.

Glues not screws

Nuts and bolts are not ideal for plastic. I

glue my 3D-printed brackets together

using Micro-Mark's Same Stuff

(

Figure 19-3

) liquid plastic welder or an

ABS-acetone slurry.

Figure 19-3.

Micro-Mark's Same Stuff

Off-the-shelf brains

The DARwIn-OP is controlled by an af-

fordable Fit-PC2 compact PC and a Ro-

botis

CM-730

servo

controller

Figure 19-2.

Meet the clone!

(

Figure 19-4

).

Here are some of the things that made this

possible:

90% DIY printed

I print my parts in ABS plastic, as PLA is

weaker and more brittle. I strongly agree

with the review of the UP! Plus/Afinia

printer in the 2012

Make: Ultimate Guide

to 3D Printing

. It's one of the best on the

market, and it has printed 90% of my

clone: servo brackets, structural framing,

and body covers.

Top servos

Robotis Dynamixel digital servomotors

are the leading robotics servos in the