Graphics Reference

In-Depth Information

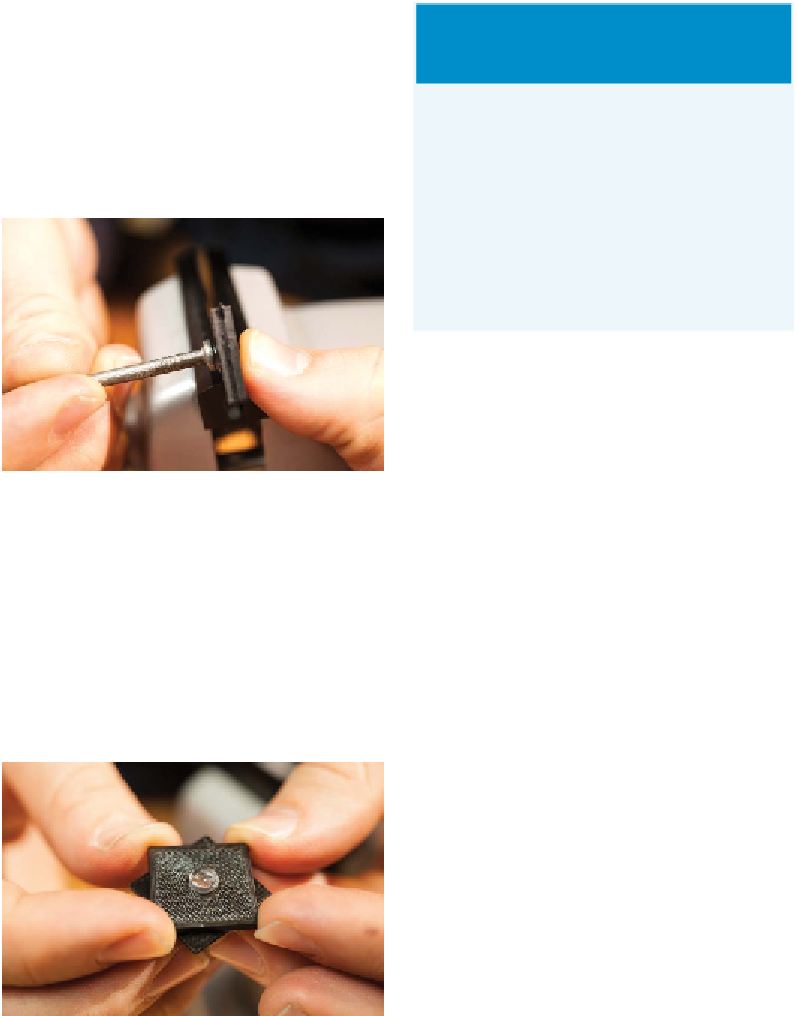

10. Continue to press tight, against the shop

head as it cools, making sure it doesn't

relax away from the mounting point.

Don't apply force to the assembly until

both the rivet and the parts being as-

sembled cool to room temperature.

Two Materials, Two Ap-

proaches to Finishing Tech

ABS and PLA plastics have very different phys-

ical properties. ABS is printed at a higher tem-

perature (typically 215-235°C), is more

durable and flexible, and dissolves in industrial

solvents like acetone. PLA can print at lower

temperatures (starting at 180°C), wears down

faster, can be brittle or shatter, and won't dis-

solve in acetone. (The chemicals used to dis-

solve PLA are highly toxic.)

Hold in place until cool as seen here:

If you'd rather use a soldering iron

than a heat gun, find a brass tube

(

Figure 13-17

) that fits snugly over

your iron. Use the brass tube to

work the plastic, and keep your sol-

dering tip clean. Make sure to clean

your tube thoroughly so the plastic

doesn't stick to the brass.

1. Installation of a hinge rivet follows the

same procedure, except at the very end.

After pressing the shop head, move the

parts gently as they cool to ensure that

the joint has enough play for the hinge

to open and close easily.

In the completed assembly, the two

black ABS plates can spin easily on the

hinge without coming free.