Geoscience Reference

In-Depth Information

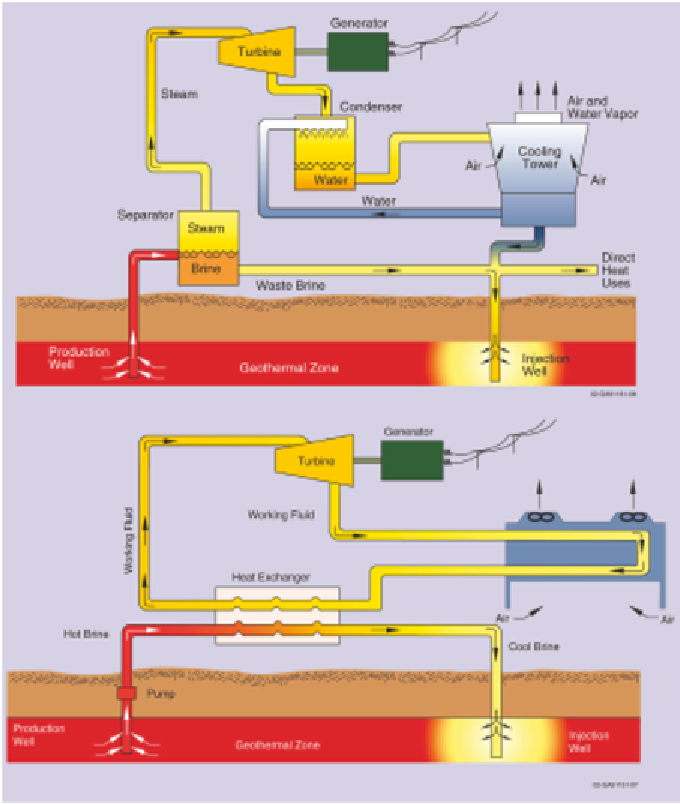

(a)

(b)

FIGURE 3.6

(a) The fluids delivered to the surface by the production wells in a flash steam power cycle

are passed through a flash vessel or separator; the separated steam that flows out of the top is directed

into a power plant where it is used to spin a steam turbine connected to a generator that produces an

electrical output. The spent steam travels through a condenser, and the condensate is then pumped to the

cooling tower, where the liquids are cooled before some of the fluids are pumped back inside the condenser

and some are combined with the water drained from the bottom of the separator and sent to the injection

wells. (b) The produced fluids for binary cycle power plants are first passed through a heat exchanger to

heat a secondary liquid, usually an organic fluid such as isopentane, which vaporizes (boils) at a lower

temperature than does water. That vaporized secondary fluid is then used to spin a turbine generator to

make electricity. Similarly, that vapor is then condensed and returned directly to the heat exchanger to be

reheated, revaporized, and recycled without any fluid loss. The produced geothermal water that has passed

through the heat exchanger is then delivered to the injection wells. SOURCE: Idaho National Laboratory.

Search WWH ::

Custom Search