Civil Engineering Reference

In-Depth Information

In contrast to near-surface-mounted reinforcement, no minimum spacing rules apply

when using externally bonded reinforcement because the bond forces are transferred

directly into the surface underneath the adhesive and there is no significant spreading of

the bond stress over the width of the member.

3.7.2 Provision of shear straps

The provision of shear straps for the adhesively bonded reinforcement can be necessary

for any of the reasons explained in the preceding sections. Generally, it is necessary to

distinguish between three cases for externally bonded shear straps:

Case 1:

The externally bonded shear strap is required for the shear design. Straps for

case 1 can also serve as end straps to prevent a concrete cover separation failure. With

such a strap, it is also possible to take into account an increase in the bond force due to

the provision of shear wrapping. The effects due to the shear force, the provision of

shear wrapping and the crack opening force

F

u

(

α

b

) should be superposed in this

situation.

Case 2:

The externally bonded shear strap serves as an end strap or is required because of

the shear wrapping according to Section 3.4.1. An increase in the bond force may be

taken into account with this strap. In this situation the effects due to the provision of

shear wrapping are to be superposed on the effect due to the crack opening force

F

u

(

α

b

).

Case 3:

The externally bonded shear strap is provided because of an increase in the bond

force. This strap may be positioned anywhere and is to be designed for the crack

opening force

F

u

(

α

b

) according to Section 3.3.4.4.

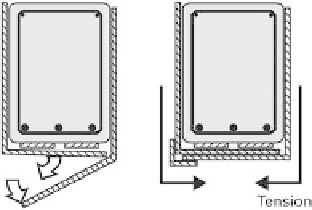

3.7.3 Steel shear straps

Shear straps made from steel plates are normally made up of two L-plates to make them

easier to install. To ensure that deformation of the member does not lead to large forces/

stress normal to the adhesive surface at the lap joint, [86] requires that a closing

L-section (see Figure 3.14) be included to prevent the plates from coming apart. When

using the shear strap to increase the bond force at the end anchorage of

flexural

strengthening according to Section 3.3.4.4, the DAfStb guideline speci

es additional

geometrical requirements to be met by the individual L-plates due to the de

nition of the

values

l

1

to

l

4

according to [82].

Fig. 3.14

Function of the closing L-section

Search WWH ::

Custom Search