Civil Engineering Reference

In-Depth Information

3.3.2 S

TEEL

R

AILWAY

B

RIDGE

S

UPERSTRUCTURES

Railway bridges transmit loads to substructures through decks, superstructures, and

bearings. The superstructure carries loads and forces with members that resist axial,

shear, and/or flexural forces.

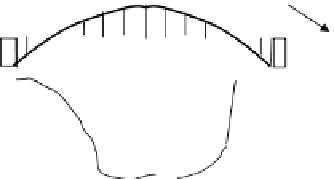

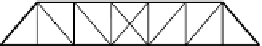

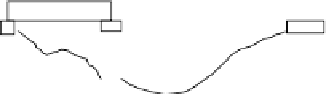

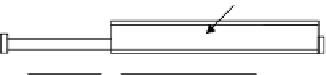

The steel superstructure forms typically used in freight railway bridge construc-

tion are beams, trusses, and arches. These superstructures have the rigidity required to

safely and reliably carry modern heavy dynamic railroad live loads and the lightness

required for transportation to, and erection at, remote locations. Beam, truss, and arch

bridges can be constructed as deck or through structures depending on the geometry

of the crossing and clearance requirements (Figure 3.12). Steel frame and suspended

structures (i.e., suspension and cable-stayed bridges) are less common but some-

times used in lighter passenger rail bridge applications. Simple span construction is

prevalent on North American freight railroads for performance,

∗

rapid erection,

†

and

maintenance considerations. AREMA (2008) recommends simple span types, based

on length, for typical modern steel railway bridges as follows:

Base-of-rail

hrough plate

girder span

Deck plate

girder span

Base-of-rail

hrough truss

span

Base-of-rail

Half-through

arch span

FIGURE 3.12

Basic forms of steel railway bridges—beams, trusses, and arches.

∗

The high railway live load to steel superstructure dead load ratio often precludes the use of continuous

spans due to uplift considerations. AREMA (2008) recommends that dead load reactions exceed live

load reactions by 50% to avoid uplift.

†

Simple span construction is generally preferred by railroads due to relative ease of erection in comparison

to continuous spans or spans requiring field splicing.