Civil Engineering Reference

In-Depth Information

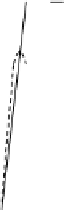

F

U3

Steel 3 = Q&T HSLA

F

Y3

F

U2

F

Y2

Steel 2 = HSLA steel

F

U1

Steel 1 = Carbon steel

F

Y1

Stress (s)

Strain ( )

0.002

FIGURE 2.1

Idealized tensile stress-strain behavior of typical bridge structural steels.

exhibited by stress-strain curves are the elastic modulus (linear slope of the initial

portion of the curve up to yield stress), the existence of yielding, and plastic behavior,

with some unrestricted flow and strain hardening, until the ultimate stress is attained.

Yield stress in tension can be measured by simple tensile tests (ASTM, 2000).Yield

stress in compression is generally assumed to be equal to that in tension.

∗

Yield stress

in shear may be established from theoretical considerations of the yield criteria. Var-

ious yield criteria have been proposed, but most are in conflict with experimental

evidencethatyieldstressisnotinfluencedbyhydrostatic(oroctahedralnormal)stress.

Two theories, the Tresca and von Mises yield criteria, meet the necessary requirement

of being pressure independent. The von Mises criterion is most suitable for ductile

materials with similar compression and tensile strength, and also accounts for the

influence of intermediate principal stress (Chen and Han, 1988; Chatterjee, 1991). It

has also been shown by experiment that the von Mises criterion best represents the

yield behavior of most metals (Chakrabarty, 2006).

The von Mises yield criterion is based on the octahedral shear stress,

τ

h

, attaining

a critical value,

τ

hY

, at yielding. The octahedral shear stress,

τ

h

, in terms of principal

stresses,

σ

1

,

σ

2

,

σ

3

is

3

(

σ

1

− σ

2

)

2

1

τ

h

=

+

(

σ

1

− σ

3

)

2

+

(

σ

2

− σ

3

)

2

.

(2.1)

Yielding in uniaxial tension will occur when

σ

1

= σ

Y

and

σ

2

= σ

3

=

0. Substitution

of these values into Equation 2.1 provides

√

2

3

σ

Y

τ

hY

=

(2.2)

∗

It is actually about 5% higher that the tensile yield stress.