Civil Engineering Reference

In-Depth Information

F

bv

f

bv

Bolt elongation

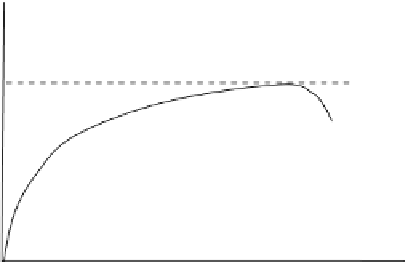

FIGURE 9.11

Bolt shear stress and elongation.

AREMA (2008) recommends only slip-resistant connections and, therefore, does

not provide an allowable stress,

f

bv

, based on shearing of the bolt shank. In slip-

resistant connections, service loads are transmitted by friction and bolt shank shearing

will not govern the design.

9.3.4.1.1.2 Allowable Effective Shear Stress in Slip-Resistant Connections

The shear slip force,

P

bv

,is

n

P

bv

=

mnf

bv

(A

b

)

=

k

s

m

α

T

bP

i

,

(9.20)

i

=

1

where

f

bv

is the effective allowable bolt shear stress;

k

s

is the shear slip coefficient

of steel connection;

m

is the number of slip planes (faying surfaces);

n

is the number

of bolts in connection;

T

bP

i

is the specified pretension in bolt

i

;

T

b

i

/T

bP

i

;

T

b

i

is

the actual pretension in bolt

i

. Therefore, the effective allowable shear stress (which

is based on the magnitude of the prestress force and the shear slip coefficient) is

α =

k

s

α

i

=

1

T

bP

i

nA

b

f

bv

=

.

(9.21a)

0.75

(A

b

)

, Equation 9.21a for A325 bolts, when the specified preten-

sion in each bolt,

T

bP

i

, is equal, becomes

Using

A

st

=

k

s

α

T

bP

i

A

b

k

s

α

(

0.70

F

bU

A

st

)

A

b

f

bv

=

=

=

63

α

k

s

.

(9.21b)

In tests done to establish an empirical relationship for the effective allowable bolt

shear stress, the slip probability level, mean slip coefficient,

k

sm

, and bolt pretension

arenotexplicitlydetermined.Theyarecombinedintoaslipfactor,

D

,thatincorporates

the

k

s

and

k

sm

relationship, and

α

of Equation 9.21b as

k

s

α

T

bP

i

A

b

f

bv

=

=

(

0.53

)Dk

sm

F

bU

=

63

Dk

sm

.

(9.22)