Civil Engineering Reference

In-Depth Information

the bolt in statically loaded structures. These are bearing-type connections. Bearing-

type connections are generally not used in steel railway superstructures because of

live load stress reversals and cyclical stresses in main members and vibration in both

main and secondary members.

9.3.1.2

Pretensioned Bolt Installation

Connections made with pretensioned bolts rely on friction between plates or element

surfaces (faying surfaces) for strength. These are slip-resistant connections and are

used extensively in modern steel railway superstructures. Pretensioned bolted joints

are made by snug-tight bolt installation followed by increasing the torque applied to

the bolt. The applied torque creates tension in the bolt (and corresponding compres-

sion of, and friction between, the connection elements). The minimum required bolt

pretension,

T

bP

,is

T

bP

≥

0.70

P

bU

≥

0.70

F

bU

A

st

,

(9.17)

where

P

bU

is the minimum specified tensile strength of the bolt;

F

bU

is the minimum

specified tensile stress of the bolt material;

A

st

is the tensile stress area of the bolt and

is equal to the cross-sectional area through the threaded portion of the bolt.

To attain this minimum bolt tension, AREMA (2008) recommends that nuts be

rotated between 1/3 and 1 turn from the snug-tight condition, depending on bolt

lengthandangleofconnectionplateswithrespecttotheboltaxis.

∗

Thiswillestablisha

pretensioninthebolt,

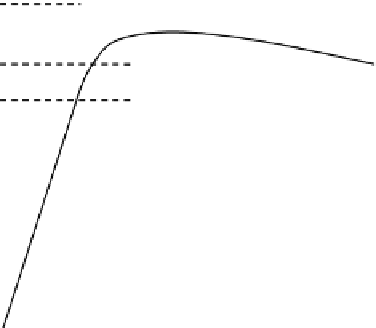

P

bP

,whichisgreaterthantheminimumrequiredboltpretension,

be made using specialized twist-off-type bolts or direct tension indicators.

P

bU

P

bP

T

bP

Bolt elongation

FIGURE 9.9

Bolt tension forces and elongation during application of bolt torque.

∗

Bolts will generally not fail until nut rotation exceeds about 1.75 times from the snug-tight condition

(Kulak, 2002).