Civil Engineering Reference

In-Depth Information

t

f

(

t

f

> t

w

)

t

2

t

1

a

=

t

1

t

w

a

=

t

w

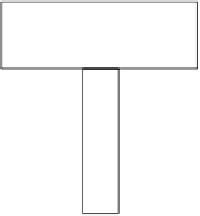

FIGURE 9.1

Size of CJP groove welds.

9.2.2.1

Groove Welds

Groove welds generally require joint preparation and may be CJP or PJP welds.

CJP welds are made through the thickness of the pieces being joined. PJP welds

are made without weld penetration through the thickness of the pieces being joined.

Groove welds are single bevel or double bevel,

∗

square,V, U, or J welds. Descriptions

of these welds and prequalification requirements

†

for both CJP and PJP welds are

shown in AWS (2005). The size,

a

, of a CJP groove weld is the thinner of the plates

joined (

Figure 9.1)

.

The size,

a

, of a PJP weld is usually the depth of the preparation

Minimum PJP groove weld sizes that ensure fusion are recommended in AWS

(2005).TheseminimumrecommendedPJPgrooveweldsizesdependonthethickness

of the thickest plate or element in the joint. The minimum PJP groove weld size

is recommended as 1/4 in. except for joints with plates or elements of base metal

thickness greater than 3/4 in. where minimum recommended weld size is 5/16 in.

However, the weld size need not exceed the thickness of the thinnest part in the joint.

PJP welds should not be used for members loaded such that there is tensile stress

normal to the effective throat of the PJP weld.

AREMA (2008) recommends only CJP groove welds be used for connections with

the exception that PJP groove welds may be used to connect plate girder flange and

web plates (T-joint in Figure 9.2).

9.2.2.2

Fillet Welds

Fillet welds do not require any joint preparation and are readily made by the SMAW,

SAW, and FCAW processes. The size of a fillet weld,

a

or

b

, is determined based on

∗

Double bevel, V, U, or J welds are generally required for plates greater than about 5/8 in. thick to avoid

excessive weld material consumption, distortion, and/or residual stresses.

†

Prequalification requirements relate to the welding process, base metal thickness, groove preparation,

welding position, and supplemental gas shielding if FCAW is used.

‡

For some welds the entire depth of preparation cannot be used and the PJP weld size may be taken as

1/8 or 1/4 in. less than the preparation depth. In the case of PJP square butt joints, the weld size should

not exceed 75% of the plate thickness.