Civil Engineering Reference

In-Depth Information

w

T

T

Δ

FIGURE 8.4

Member subjected to combined tensile axial force and bending.

may be applied to ensure that failure by yielding does not occur. AREMA (2008)

recommends that, if bending (even with superimposed axial tensile stresses) causes

compression in some parts of the cross section, the flexural compressive stress and

stability criteria should be considered. Therefore, the allowable flexural stress may

differ from the allowable axial tensile stress, which provides the interaction equation

±

σ

b

F

b

+

σ

t

F

t

≤

1,

(8.25)

where

σ

t

is the maximum

tensile axial stress,

F

b

is the allowable tensile or compressive bending stress,

F

t

is the

allowable axial tensile stress on the gross section and is equal to 0.55

F

y

.

When flexural compression with axial tension results in tensile stresses, Equa-

tion 8.25 is

σ

b

is the maximum tensile or compressive bending stress,

σ

b

+ σ

t

≤

0.55

F

y

,

(8.26)

which is theAREMA (2008) recommendation.When flexural compression with axial

tension results in compressive stresses, AREMA (2008) recommends

−σ

b

+ σ

t

≤

F

call

,

(8.27)

where

F

call

is the allowable compressive bending stress.

8.4.2 A

XIAL

C

OMPRESSION AND

U

NIAXIAL

B

ENDING

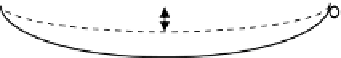

The compressive load increases the bending effects on the member when compressive

axial loads act simultaneously with bending (Figure 8.5). For the beam shown in

Figure 8.5

wL

2

8

+

M

=

P

Δ

.

(8.28)

Again, the deflection,

, is dependent on the bending moment,

M

, which is itself

dependent on the deflection

Δ

. The deflection is

Δ

5

wL

4

384

EI

+

L

2

8

EI

P

Δ

Δ =

(8.29)