Civil Engineering Reference

In-Depth Information

tangent modulus is often used in the development of modern inelastic compression

curves and equations.

The tangent modulus theory (Equation 6.25) includes material imperfection con-

siderations but it does not explicitly consider the effects of geometric imperfections

(member out-of-straightness) and residual stresses in compression members.

Geometricimperfections(unintentionalmemberout-of-straightnessandeccentric-

ity) have a detrimental effect on the inelastic critical buckling force of compression

members of relatively large slenderness.TheAmerican Institute of Steel Construction

(AISC, 1980) ASD provisions recognize this by increasing the factor of safety, FS,

to 115% of 5/3 for compression members with an effective slenderness ratio at the

value for Euler elastic buckling,

C

c

=

KL/r

. This variable FS is

(KL/r)

C

c

3

5

3

+

3

8

(KL/r)

C

c

1

8

FS

=

−

for

(KL/r)

≤

C

c

(6.27)

Geometric imperfections are also implicitly recognized in the AREMA (2008)

recommendations through the use of a higher, although constant, FS for axial com-

pression (FS

1.82).A similar cubic

polynomial as Equation 6.27 was used in Chapter 5 to investigate a variable FS using

the AREMA (2008) criteria. However, due to the potential for geometric imperfec-

tions to create greater instability for members loaded with relatively large-magnitude

live loads, the higher factor of safety is likely to be appropriate even for less slender

compression members in railway bridges.

The rolling of structural steel plates and shapes, and fabrication bending, cut-

ting, and/or welding procedures may create residual stresses that affect the inelastic

critical buckling stress in a compression member. The pattern of compressive and

tensile residual stresses is very dependent on member cross section and dimensions.

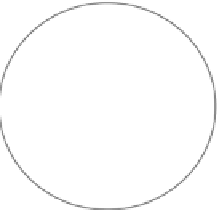

The presence of varying residual stresses will affect the material compressive stress-

strain curve (Figure 6.8) and establish a different effective modulus of elasticity in

each direction across a compression member cross section. If the tangent modulus is

taken as the effective modulus of elasticity, it will differ depending on the direction

=

1.95) than what is used for axial tension (FS

=

Members with residual stress

(from short column tests)

F

p

Theoretical

(coupon tests)

F

Y

Stress

F

p

Compressive strain

FIGURE 6.8

Typical compressive stress-strain curve for structural steel.