Biomedical Engineering Reference

In-Depth Information

Maize stalk fibers are obtained from the farm field by local resources and it is

cleaned manually and later thoroughly washed in running water and the fibers were

sun dried. These fibers were decorticated properly and later chemically treated by 5%

NaOH solution. The fibers were chopped into random pieces of uniform length. The

obtained fibers were kept in an oven at around 60°C for 120 min and later used for

the work. The natural fibers are now ready to use as a fiber material for processing.

The VARTM method of processing composites is carried out efficiently with no voids

and spaces around the mold. The laminate is sealed within an airtight envelope. When

the bag is sealed, pressure on the outside and inside of this envelope is equal to the

atmospheric pressure. The matrix material used is a thermosetting resin of unsaturated

polyester resin mixed with methyl ethyl ketone peroxide as a catalyst and cobalt oc-

toate as a promoter. The detailed work is depicted in

Figure 2

.

The composites pre-

pared were examined for integrity of fiber with the resin and confirmed that the maize

fibers are suitable reinforcements for composites.

results aNd disCussioNs

Plant based natural fibers are lignocellulosic, consisting of cellulose micro fibrils in an

amorphous matrix of lignin and hemicellulose. To improve the incorporation of natu-

ral fibers into polymers and to have higher fiber/matrix interfacial adhesion, natural

fibers can be altered by different physical and chemical treatments.

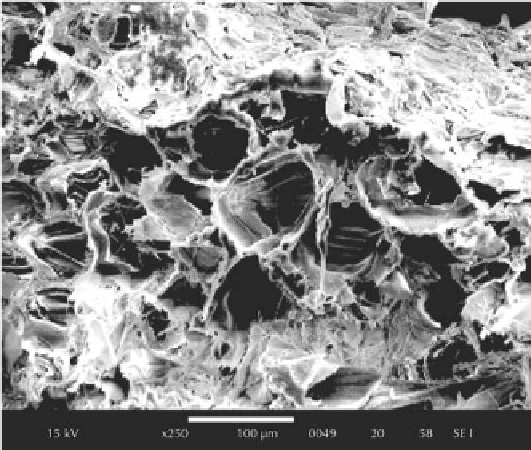

Figure 3.

Scanning electron micrographs of raw maize fiber.

Fiber samples were sputtered and placed in for analyzing using scanning elec-

tron microscope. Figure (3,

4)

reveals the cross section of raw maize fiber. It has a

thick layer of protective material and cellular deposits and also presence of lumen

Search WWH ::

Custom Search