Biomedical Engineering Reference

In-Depth Information

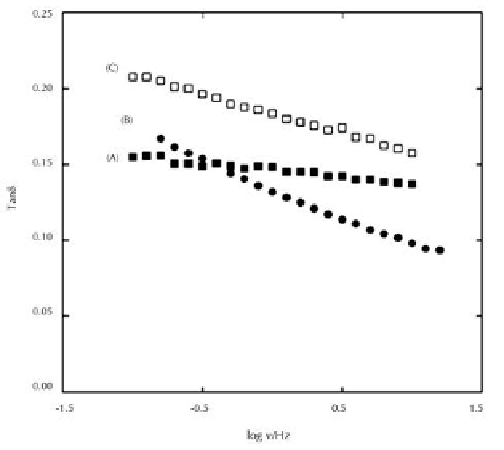

erature value (Roberts, 1988). When we form the nanomatrix structure, the tand of the

product increased dramatically at high frequency region but a little at low frequency

region. After annealing the product at 130°C, the tand increased significantly over

whole frequency range at plateau region. This may be explained to be due to the well-

connected nanomatrix at 130°C but less-connected one at 30°C. Thus, the product

was proved to accomplish not only high storage modulus but also outstanding loss

modulus, where tand is a ratio of loss modulus to storage modulus. The difference in

the storage modulus and loss tangent at the plateau region must come from a change

in the morphology.

Based upon the three-dimensional observation at low and extremely high mag-

nifications, the 10 times increase in the storage modulus may be associated with the

flocculation of the polystyrene-granules to form the nanomatrix structure, which is

distinguished from the isolated dispersoid in the island-matrix structure. The less than

several nano-metric spaces between the granules in the nanomatrix enable them to

interfere to increase the storage modulus. The further increase in the plateau-modulus,

that is 35 times, may be explained to be due to the connected nanomatrix after anneal-

ing. In an ordinary circumstance, the minor hard-component in the multi component

system, consisting of hard and soft components, is known to become the island phase

in the island-matrix-structure for polymer blends or block- and graft-copolymers. In

this case, little increase in the modulus is anticipated for the multi component systems.

In contrast, it is difficult to form co-continuous structure for the natural rubber/poly-

styrene 90:10 blend. Only by forming the nanomatrix of the minor component, we will

create tough, functional materials, which we have never seen.

Figure 13.

Loss tangent at plateau region versus frequency for (A) natural rubber, (B) DPNR-graft-PS

(PS: ca 10%) with the nanomatrix structure annealed at 30

o

C and (C) DPNR-graft-PS (PS: ca 10%)

with the nanomatrix structure annealed at 130

o

C. The loss tangent increased at high frequency region

after forming the nanomatrix structure, and it increased significantly after annealing it at 130

o

C.

Search WWH ::

Custom Search