Biomedical Engineering Reference

In-Depth Information

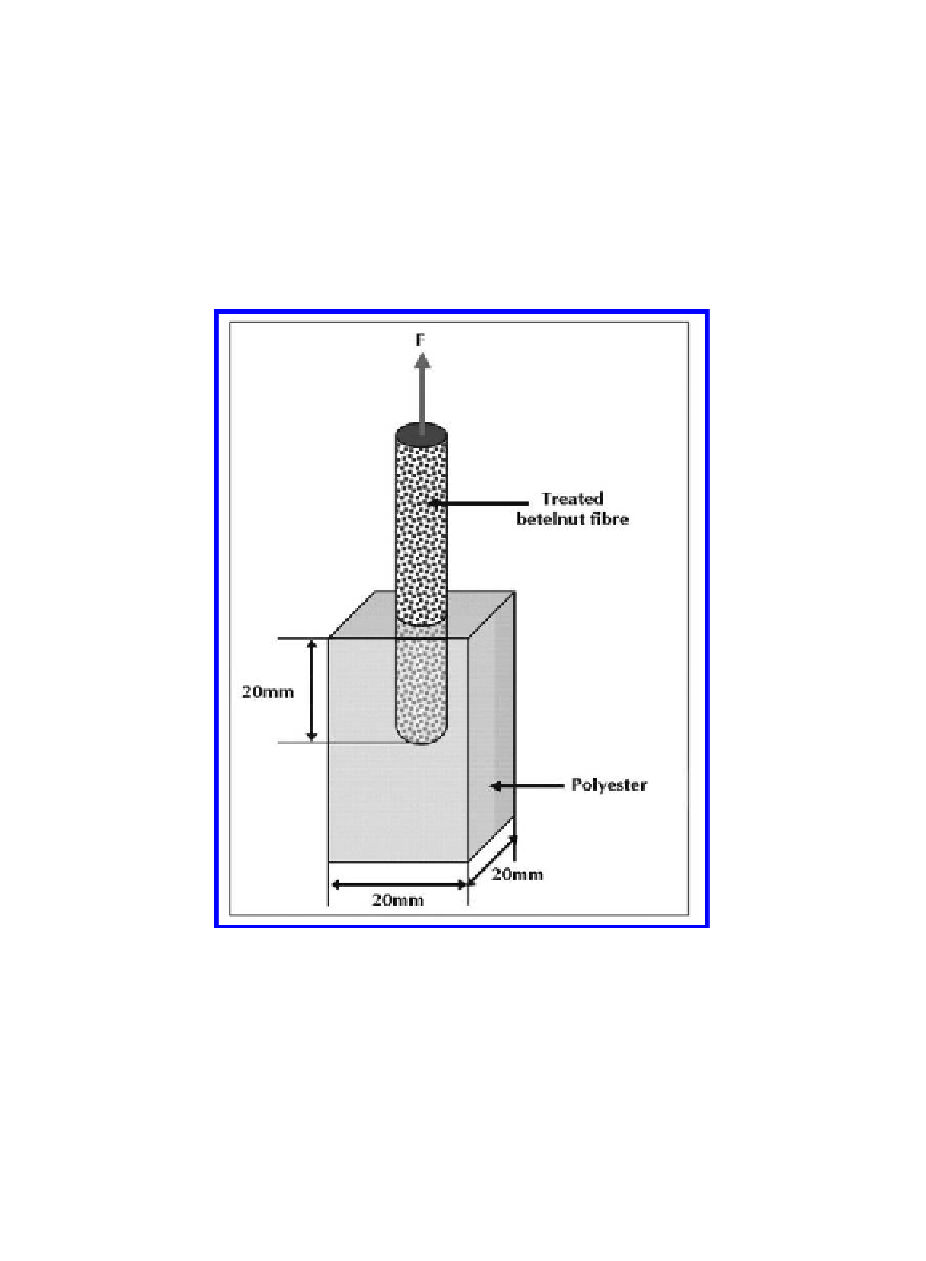

Fiber Pullout test

The SFPT were conducted on universal test system (100 Q Standalone) to determine

the interfacial adhesion characteristics of treated betelnut fiber with the polyester ma-

trix. Figure 2 shows the schematic drawing of the pullout test. Further detail on the

sample preparation and the test procedure were explained in the past publication done

by the author (Nirmal and Yousif, 2009). The loading speed was 1 mm/min. It should

be mentioned here that the tensile properties of single betelnut fiber were studied for

dry and wet fibers. Under wet conditions, the fibers were soaked in tap water (hardness

120-130 mg/l) for 24 hr and then tested.

Figure 2.

Schematic illustration of single betelnut fiber pullout test.

The pullout result for single fiber (dry/wet) is presented in

Figure 3(a).

The Figure

shows that both trends (under dry/wet) are the same. The maximum stress for the dry

fiber is about 280 MPa which is almost similar to the single fiber strength. Similarly,

the wet fiber reached to about 250 MPa. This indicates that there is no pullout of fiber

took place during the test. Moreover, the strength is also the same as the single tensile

result. This shows that the interfacial adhesion of the treated fiber under dry/wet con-

ditions is very high preventing the pulling out process. The microscopy of the pullout

samples are shown in Figures 3(b) and (c) which explain the above results.

Search WWH ::

Custom Search