Biomedical Engineering Reference

In-Depth Information

Newly formed bone and increase in total bone area were unevenly distributed

along the length of the actuators; significant differences when comparing actuators to

static controls arose from the two distal thirds of the devices. No differences in total

bone area and new bone area were found in the actuators encastre region (clamped

region). These findings are in agreement with the previous Finite Numerical Method

and ESPI method studies on the displacement of the piezoelectric films under the ex-

perimental conditions.

Immunohistochemistry shows a marked elevation in osteopontin detection around

actuators, in A3 and A4 (Figure 8). Since it is known that OPN production is increased

in association with mechanical loading (Harter et al., 1995; Perrien et al., 2002), the

increased expression we found around actuators' areas of higher deformation, when

comparing to static controls, is most likely associated with mechanical stress. No

marked differences were found in PCNA detection.

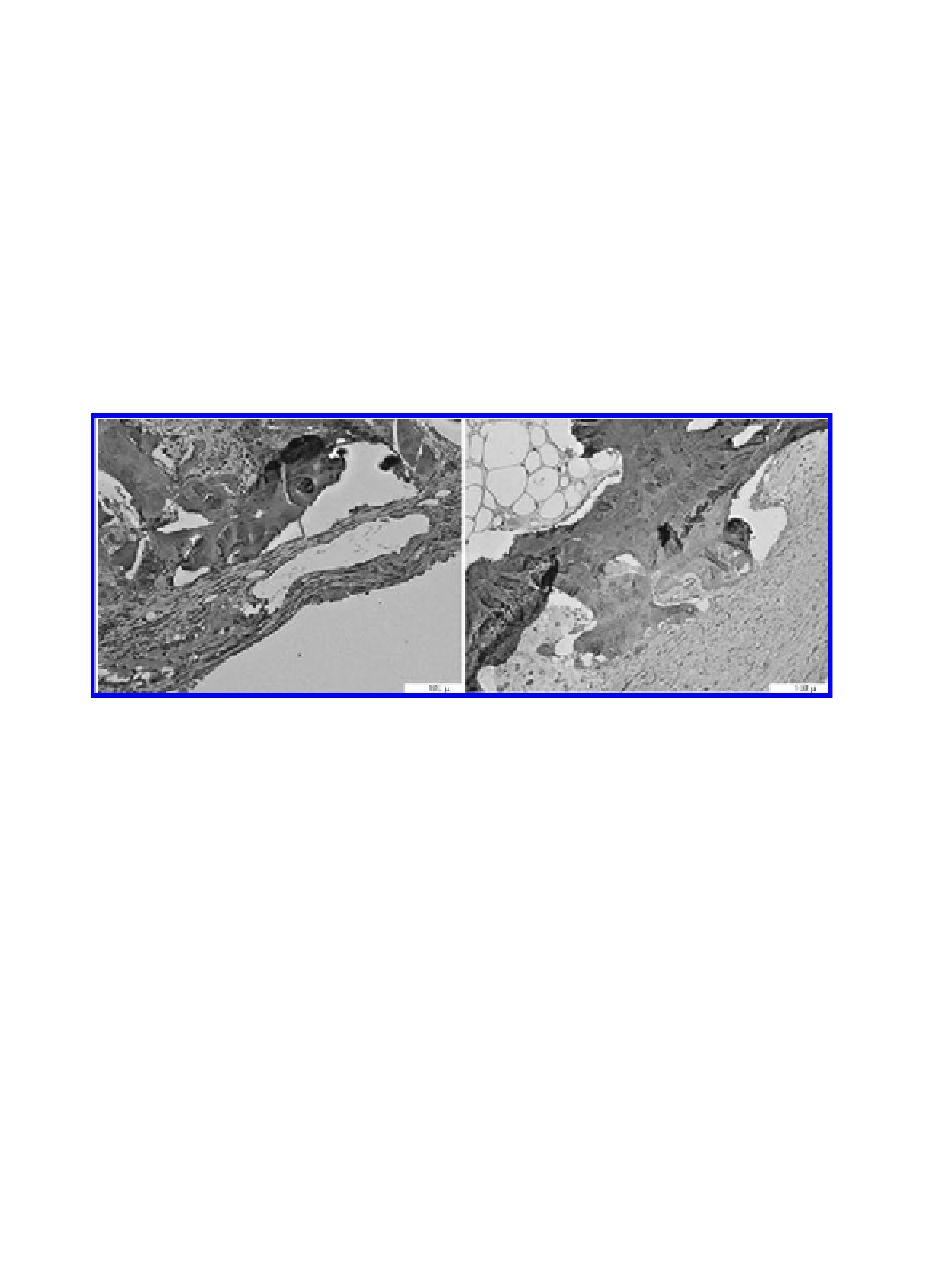

Figure 8.

Microphotograph of decalcified sections, double Fast-Red and DAB immunohistochemistry

staining for osteopontin and PCNA, respectively. Picture shows A3 areas of actuator (on the left) and

static control (on the right), evidencing much more extensive osteopontin labelling around actuator.

Scale bar represents 100 µm.

Osteocalcin detection was also increased around actuators, when compared to con-

trols (

Figure 9)

.

Osteocalcin is a non-collagenous protein and a major constituent of

bone matrix; it is produced by osteoblasts and binds strongly to hydroxyapatite; osteo-

calcin is considered a sensitive marker of bone formation, and it has been described as

rising as consequence of mechanical stimulation-induced cell differentiation (Mikuni-

Takagaki, 1999; Pavlin et al., 2001).

We observed that all the devices were separated from neighbouring bone by a

fibrous capsule with an average thickness of 292 µm. This is probably due to the mate-

rial itself, since the fibrous capsule was obvious both in actuators and static devices,

with no statistical significant differences in capsule thickness between the two groups

(289.59 ± 131.20 µm in actuated films vs 293.93 ± 84.79 µm). It would be mandatory

to develop and test a material with improved biocompatibility to evaluate accurately

the bone material interface.

Search WWH ::

Custom Search