Biomedical Engineering Reference

In-Depth Information

table 5.

(Continued)

Composite

Removed mass using one gram of the resin (g/g)

Petroleum (8)

Petroleum (12)

Petroleum (16)

RAM4

8.6 ± 0.2

13.2 ± 0.5

17.9 ± 0.4

RAM5A

9.0 ± 0.3

14.6 ± 0.6

17.3 ± 0.5

RAM5B

9.3 ± 0.7

13.0 ± 1.0

17.1 ± 0.5

RAM5C

9.7 ± 0.2

13.6 ± 1.1

18.0 ± 0.8

The effect of the amount of the oil, phthalic anhydride, and castor oil on the pe-

troleum removal capability of the resins was evaluated using the DoE technique. The

obtained results are shown in Table 6.

table 6.

Oil removal answers to the composites from different alkyd resin.

Factors

Effect

Standard Error

p

Average

1.3128E+1

7.6107E-2

0.0000E+0

(1) Petroleum(L)

8.1358E+0

1.8307E-1

0.0000E+0

Petroleum(Q)

-7.9000E-2

1.5854E-1

6.2018E-1

(2) Anhydride(L)

2.9614E-1

1.9773E-1

1.3974E-1

Anhydride.(Q)

4.7381E-1

1.5102E-1

2.6970E-3

(3) Castor oil (L)

6.2100E-2

1.9773E-1

7.5461E-1

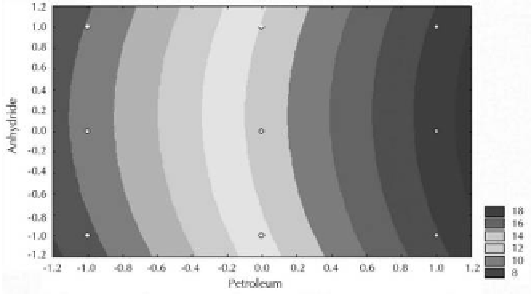

The obtained results show that the phthalic anhydride amount presents a quadratic

effect on the oil removal capability, while the petroleum amount presents a linear effect.

Figure 20 shows the oil removal capability as a function of the petroleum and an-

hydride amount. It is easier to observe that the increase of the anhydride amount leads

to the increase of the oil removal capability possibly associated with a best aromatic/

aliphatic balance. In addition, the increase of the petroleum amount leads to the in-

crease of the oil removal capability.

Figure 20.

Oil removal capability as a function of the petroleum and phtalic anhydride amounts.

Search WWH ::

Custom Search