Biomedical Engineering Reference

In-Depth Information

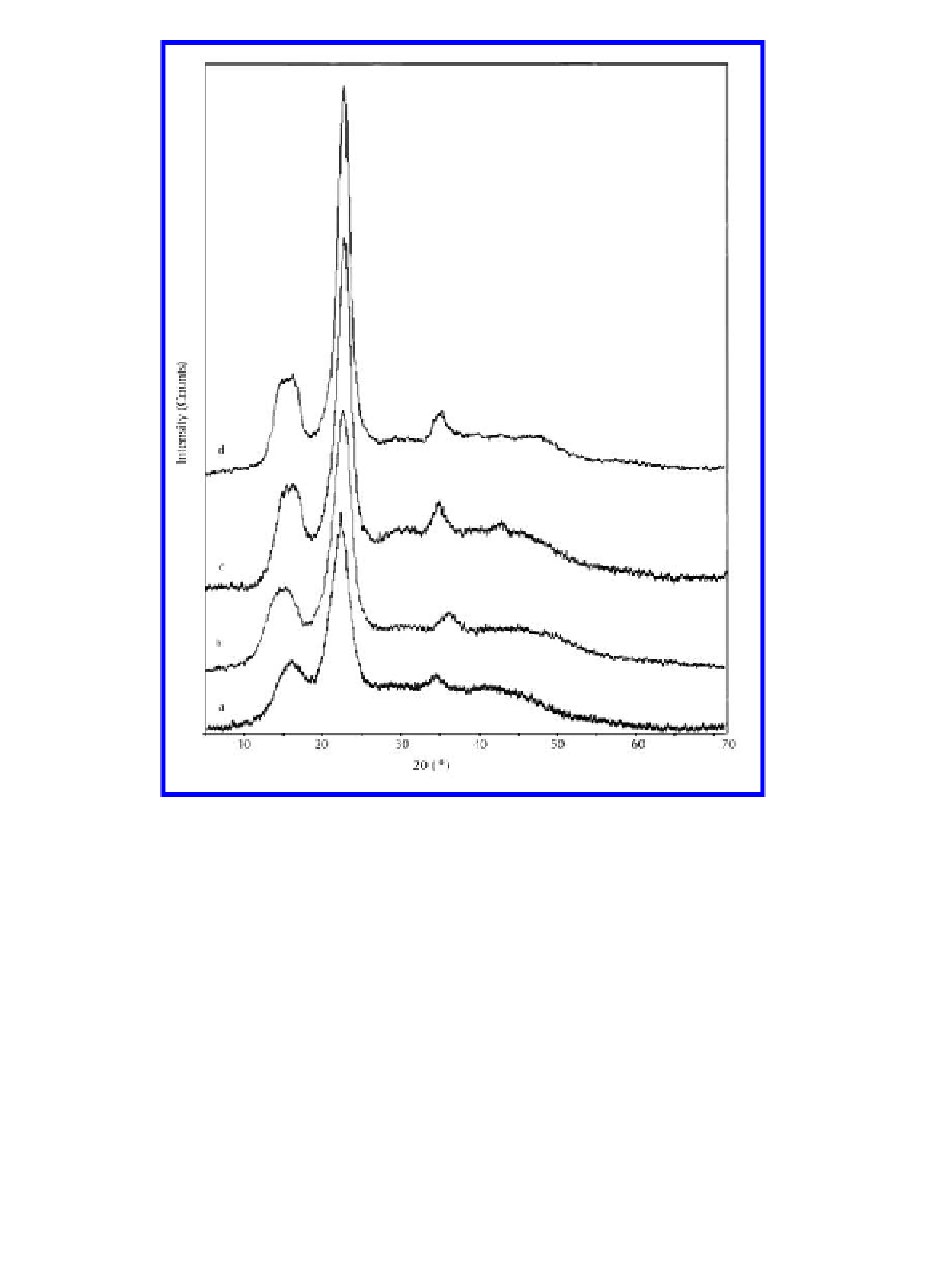

Figure 6.

X-ray diffraction pattern of (a) Rae kenaf fibre, (b) Alkali treated kenaf fibre, (c) Bleached

kenaf fibre, (d) cellulose nanowhiskers.

Moreover, after hydrolysis, the hydronium ions could penetrate into the amor-

phous regions of cellulose promoting the hydrolytic cleavage of glycosidic bonds and

finally releasing the individual crystallines (de Souze Lima and Brosali, 2004) and

increase the degree of crystallinity. It is believed that the higher crystallinity leads to

higher tensile strength of the fiber and thereby improved mechanical properties of the

corresponding nanocomposites (Alemdar and Sain, 2008).

tGa analysis

The thermal degradation behavior of raw fiber, alkali treated fiber, bleached fiber and

CNW investigated from TGA and DTA measurements (

Figure 7)

.

The TGA curve il-

lustrates an initial weight loss about 4% during heating to 100°C which corresponds

to vaporization and removal of water in fibers. Due to the differences in the chemical

structure between hemicelluloses, cellulose and lignin, they usually decompose at dif-

ferent temperatures (Yang et al., 2007).

Search WWH ::

Custom Search