Biomedical Engineering Reference

In-Depth Information

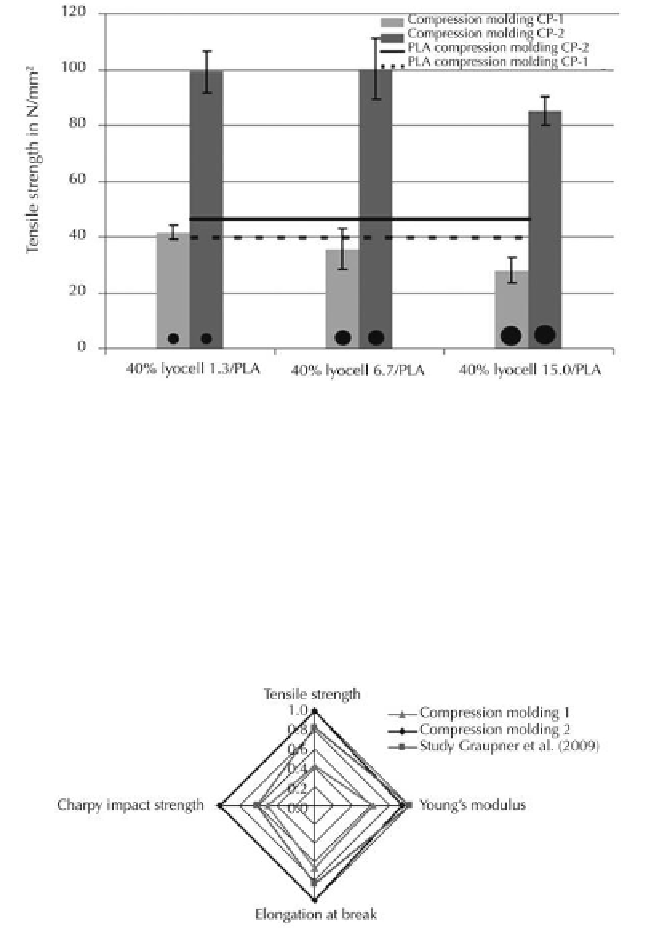

The tensile strength of the composites reinforced with fiber loads of 40 mass%

reached 99 N/mm² for the lyocell 1.3-PLA composites, 100 N/mm² for the lyocell 6.7-

PLA composites and 85 N/mm² for the lyocell 15.0-PLA composites (Figure 10). The

Charpy impact strength increased from 33 to 66 kJ/m² for lyocell 1.3-PLA composites,

from 39 to 43 N/mm² for the lyocell 6.7-PLA composites and from 31 to 54 kJ/mm² for

the lyocell 15.0-PLA composites.

Figure 10.

Influence of the processing parameters on the multilayer web reinforced PLA composites

and the neat PLA matrix (mean values, standard deviations are shown as error bars; dots show the

dimension of the fiber diameter).

A comparison of the mechanical characteristics of 40 mass% lyocell 1.3-PLA

composites produced by different compression molding techniques is shown in Figure

11. The highest mechanical characteristics were achieved by using compression mold-

ing technique CP-2 followed by the compression molding technique used in the study

Graupner et al. (2009). By far the lowest composite characteristics were measured for

the composites produced by compression molding technique CP-1 due to a low degree

of compaction and weak interfacial interactions in the composites.

Figure 11.

Comparison of the mechanical characteristics of 40 mass% multilayer web reinforced

lyocell 1.3-PLA composites (highest values = 1).

Search WWH ::

Custom Search