Biomedical Engineering Reference

In-Depth Information

modulus increased by 30% (with 5% BC), while the elongation at break was reduced

from 144 to 24%. These results can be explained by the inherent morphology of BC

with its nano- and micro-fibrillar network.

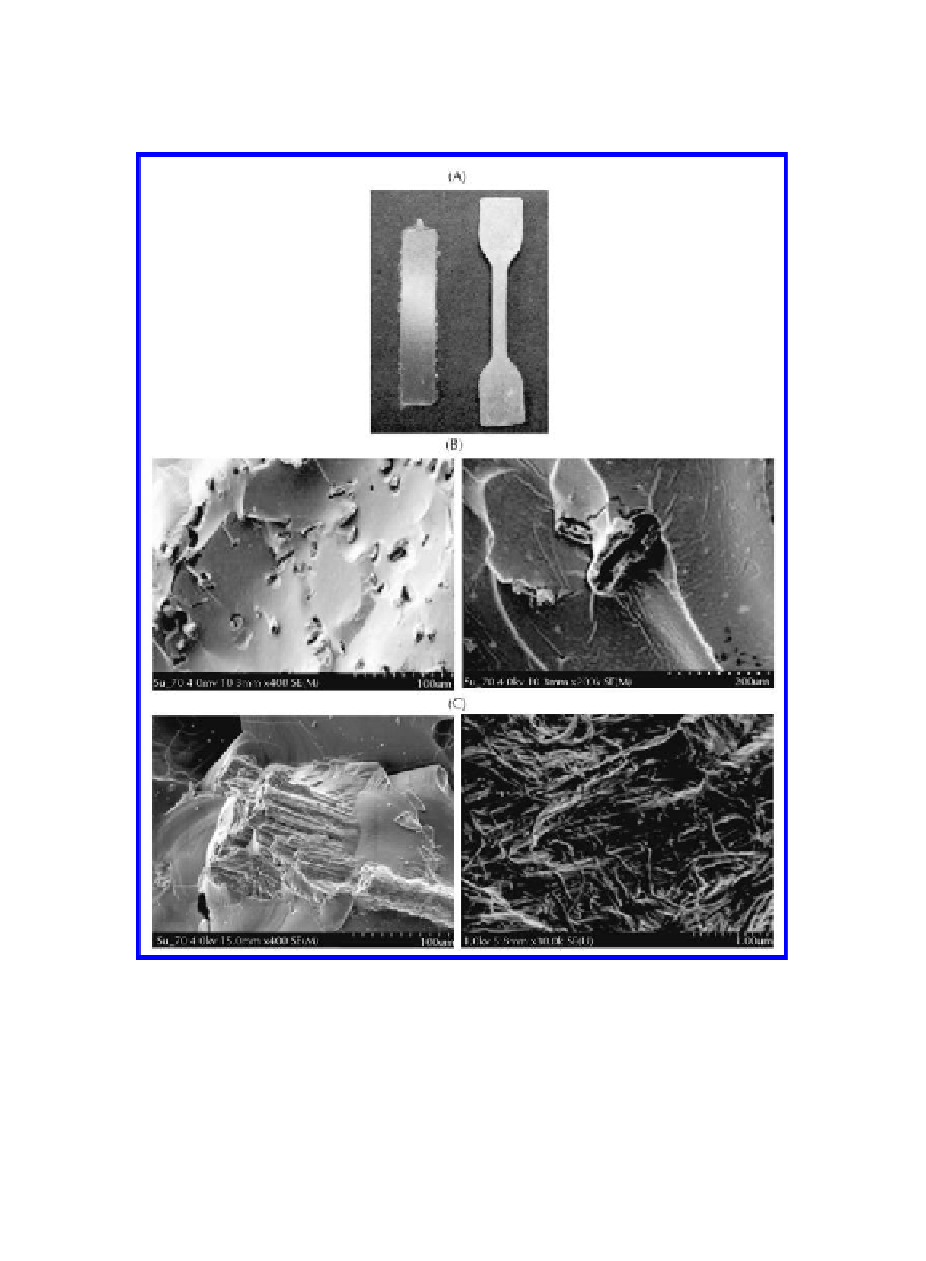

Figure 5.

Images of composites (A) and SEM micrographs of TPS nanocomposites with 5 wt% of VC

(B) and BC (C).

This study provides an initial insight into the use and characteristics of bacterial

cellulose in starch-based composites. Bacterial cellulose acts efficiently as reinforce-

ment, even in relatively low quantities, since 5% produced a significant increase in

both modulus and tensile strength. These materials are promising candidates in appli-

cations like food packaging and biodegradable artifacts. However, the ensuing com-

posites displayed a strong sensitivity to high relative humidity.

Search WWH ::

Custom Search