Biomedical Engineering Reference

In-Depth Information

published. One practical application of chitosan-cellulose mixtures is their processing

into films, having high strength parameters and also good biocompatibility, biodegrad-

ability and hydrophilicity. More recently, the incorporation of micro and nanofibers

cellulose into several polymeric matrices, gave materials with superior mechanical,

thermal and barrier properties and transparency when compared with the conventional

fibers. Some studies have been published dealing with the preparation and character-

ization of NFC or BC based-nanocomposites with chitosan (Ciechanska, 2004; Dubey,

2005; Fernandes, 2009, 2010; Hosokawa, 1990, 1991; Nordqvist, 2007).

Transparent films have been obtained from mixtures of chitosan and both BC and

NFC nanofibers (Fernandes, 2009, 2010). The chitosan solutions were shown to be an

efficient media to prepare stable suspensions of NFC or BC, and to produce transpar-

ent films with a very homogeneous distribution of BC and NFC (Figure 4).

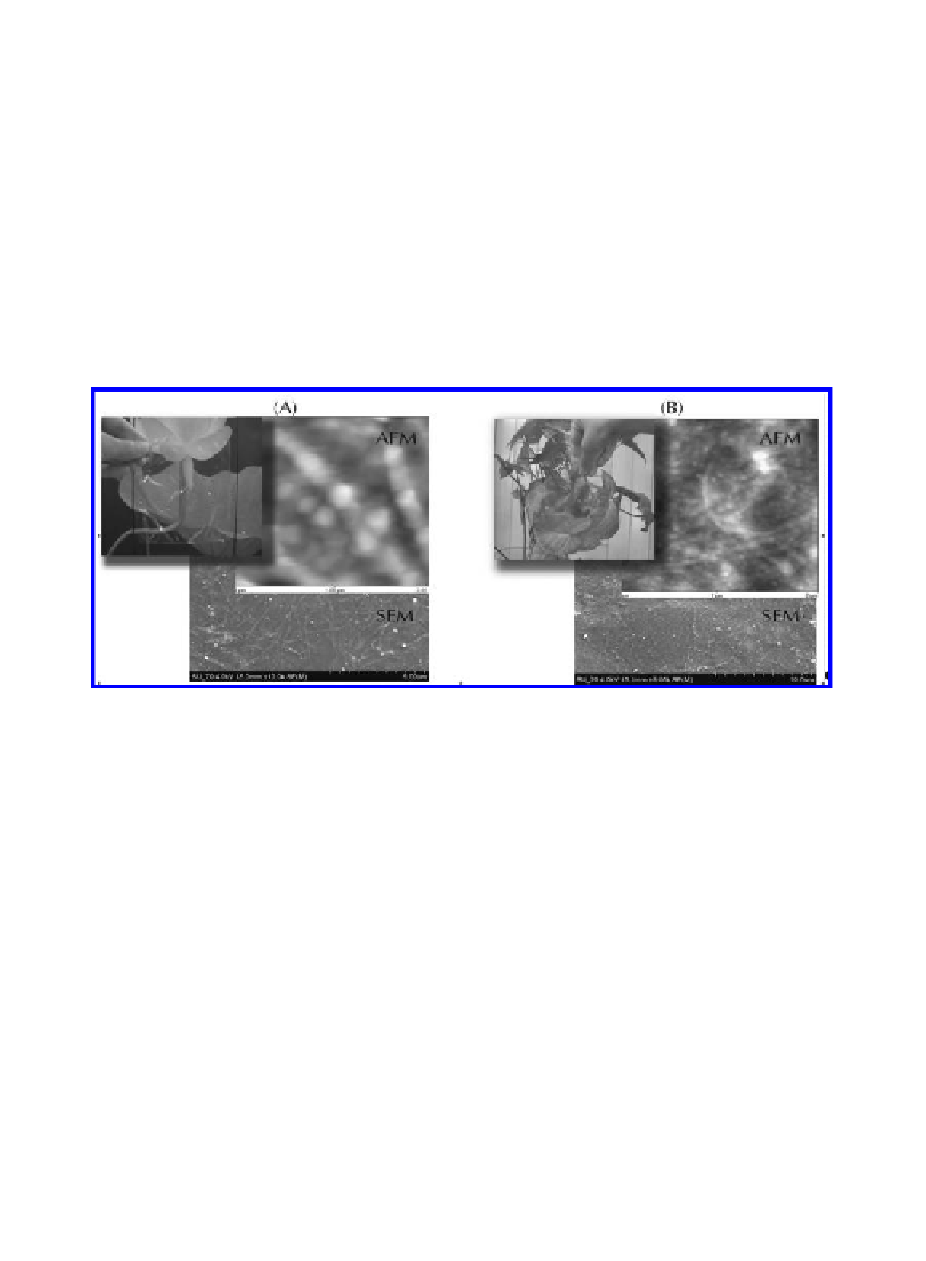

Figure 4.

Images and AFM/SEM micrographs of transparent nanocomposite films of chitosan with

BC (A) and NFC (B).

Chitosan- and water-soluble chitosan-cellulose nanofiber nanocomposite films

were prepared by a simple and green procedure based on casting water (or 1% acetic

solutions) suspensions of chitosan with different contents of NFC (up to 60%), and BC

(up to 40%). The transparency of the films obtained indicated that the dispersion of

the NFC and BC into the chitosan matrices was quite good. The nanocomposite films

prepared with BC showed higher transmittance than the corresponding films prepared

with NFC, because of the higher purity of BC.

The ensuing materials were in general very homogenous and presented better

thermo-mechanical and mechanical properties than the corresponding unfilled chito-

san films. With the NFC and BC addition to the chitosan's matrices, tensile strength

and Youngs modulus were completely dominated by the NFC and BC network. The

superior mechanical properties of all nanocomposite films, compared with those of

the unfilled CH films, confirmed the good interfacial adhesion and the strong interac-

tions between the two components. These results can be explained by the inherent

morphology of BC with its nanofibrillar network, the high aspect ratio of NFC and

the similar structures of the two polysaccharides. The nanocomposite films presented

Search WWH ::

Custom Search