Biomedical Engineering Reference

In-Depth Information

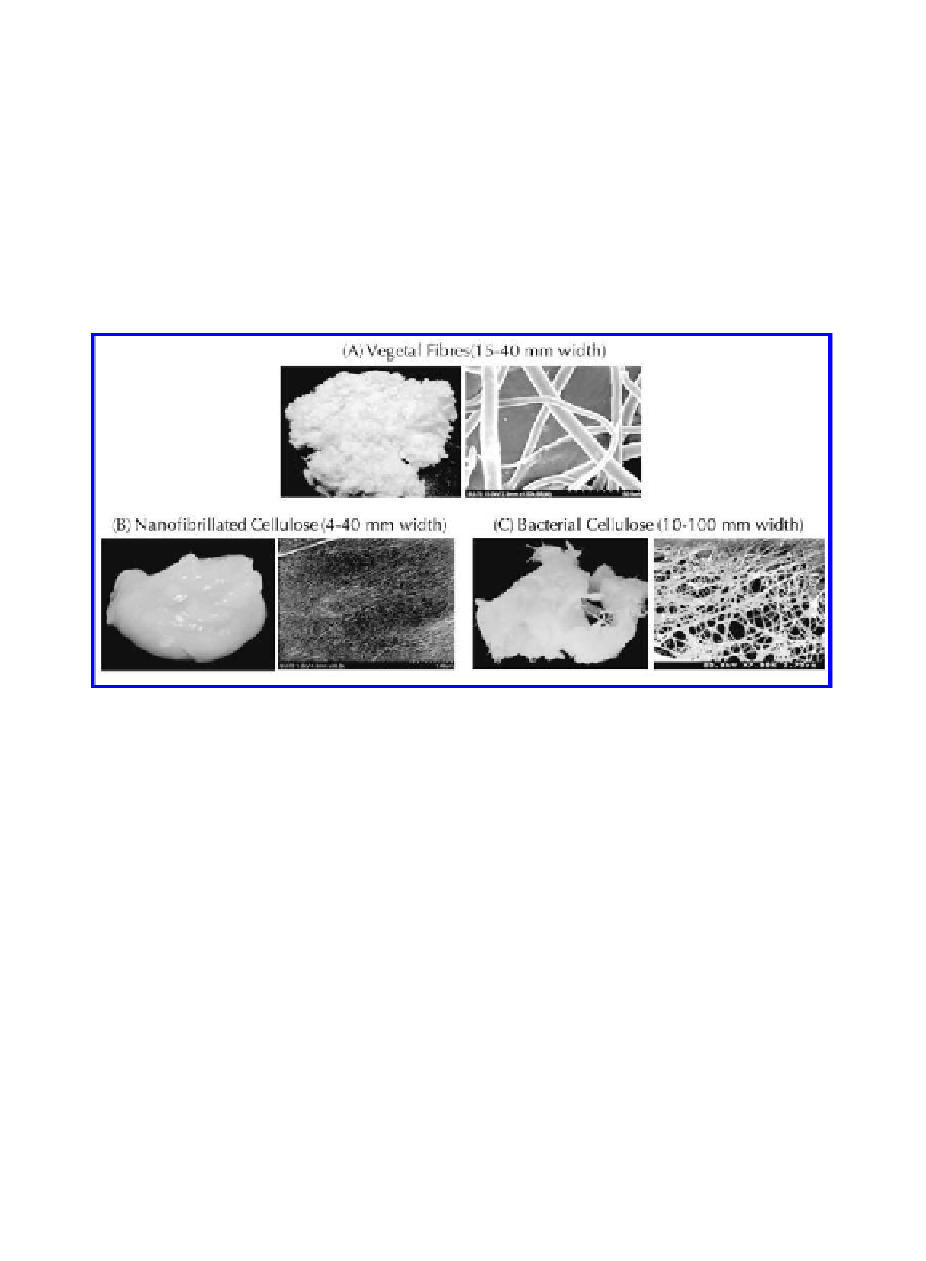

Bacterial cellulose (BC) (Figure 1C), also known as microbial cellulose, is pro-

duced by the biosynthesis of different genus of bacteria, for example of the

Glucona-

cetobacter

genus. The BC is generated as a three-dimensional network of cellulose

nano- and microfibrils with 10-100 nm diameter, that is about 100 times thinner than

typical vegetal cellulose fibers. The microfibrillar structure of bacterial cellulose is

responsible for most of its properties. Bacterial cellulose possesses very high purity

(free of lignin, hemicelluloses, and the other natural components usually associated

with plant cellulose) a high degree of polymerization and crystallinity, extremely high

water binding capacity, high tensile strength and of course a higher surface area, as

compared to the widespread plant-based counterparts (Pecoraro, 2008).

Figure 1.

(A) Visual and SEM micrographs of vegetal cellulose, (B) nanofibrillated, and (C) bacterial

cellulose.

The use of cellulose in different forms as reinforcing agent for matrices of other

polysaccharides that bear promising functional properties but, poor mechanical fea-

tures opened wide perspectives on the preparation of a wide range of promising func-

tional materials through simple and green processes: due to the structural similarity of

both cellulose fibers and polysaccharide matrices, the former can be used as reinforc-

ing elements without any chemical modification. Two of the most interesting examples

of polysaccharides matrices in which various cellulose forms can play an interesting

role as reinforcing agents are starch and chitosan.

Starch

(

Figure 2),

a mixture of amylose and amylopectin, is also one of the most

abundant natural polymers and is considered as a promising raw material for the de-

velopment of novel materials, including biocomposites. It can be converted into a

thermoplastic material, known as thermoplastic starch (TPS), through the disruption

of the molecular chain interactions under specific conditions, in the presence of a plas-

ticizer (Carvalho, 2008). Water and glycerol are the most widely used plasticizers in

the production of TPS.

Search WWH ::

Custom Search