Biomedical Engineering Reference

In-Depth Information

Comparison of

----in situ

Grafting Polymer with literature Pre-grafting

Polymer technique

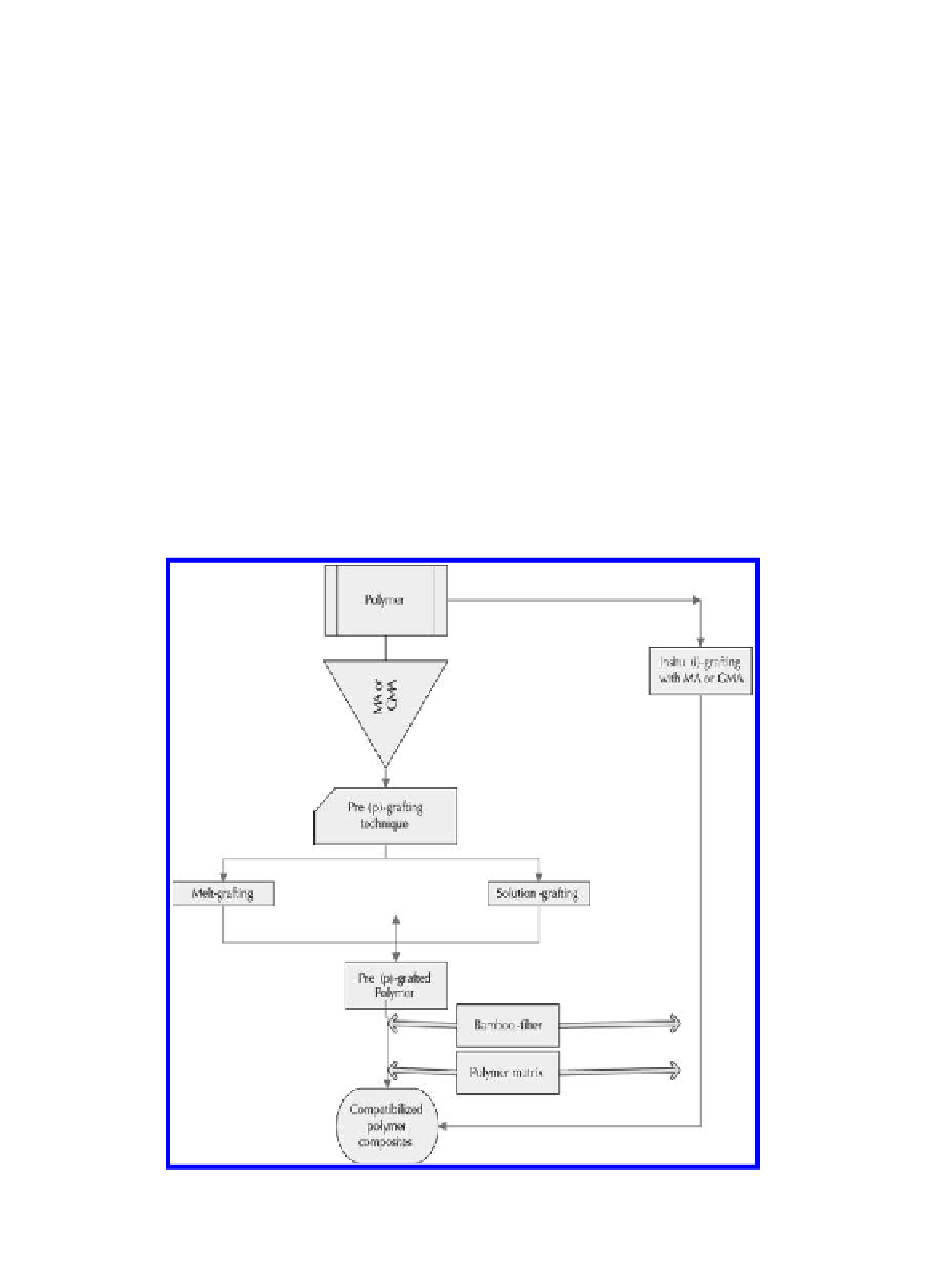

The melt grafting (Chen et al., 1996; Jang et al., 2001; Kim et al., 2001)/ radiation-

induced grafting (Choi et al., 1998) of glycidyl methacrylate (GMA) or solution sur-

face grafting (Chen et al., 1998; Heinen et al., 1996; Machado et al., 2001) / UV

pre-irradiation step grafting (Martínez et al., 2004)/ melt grafting (Heinen et al., 1996;

Machado et al., 2001; Shi et al., 2001) /Ball- milling grafting technique (Qiu et al.,

2005) of MA onto PP/PE (various form like powder, fiber and granules) are discussed

in literature. These pre-grafting techniques are very tedious, time taking process and

wastage of money or energy. Therefore, it is good to fabricate composites with

----in

situ

grafting techniques. Figure 9 shows the flow chart of making bamboo-fiber com-

posites with p-grafted or

----in situ

grafted polymer as a compatibilizer. The

----in situ

grafting revealed a considerable grafted weight of MA or GMA. Finally,

----in situ

MA grafted polymer (≥1.2%) composites showed a good tensile strength comparable

to pre-grafted polymer composites but the thermal stability was little bit poor because

free MA group might be present in the system while in p-grafted system free MA

group was removed by purification technique. Hence, if better optimal control on the

----in situ

grafting is maintained in a way so that no free MA/ GMA group are present,

the composites compatibilized with

----in situ

grafting can give better properties.

Figure 9.

Flow chart of grafting technique to obtained compatibilized composites.

Search WWH ::

Custom Search