Biomedical Engineering Reference

In-Depth Information

kind of

----in situ

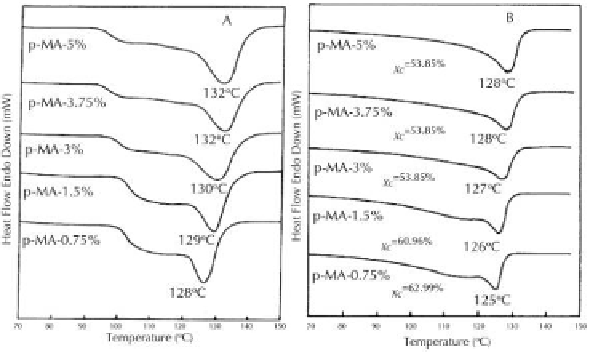

MA/GMA compatibilized composites with the increase in the con-

tent of monomer (MA/GMA). The second heating scans were used to determine the

crystallinity index of the matrix in the composites. The crystallinity index of uncom-

patibilized LLDPE/30 wt%-SDBF composite was 62.99% (Kumar et al., 2010). The

crystallinity index of matrix decreased with increasing amounts of p-MA and i-GMA

grafted polymer while it increased for i-MA grafted polymer with increasing of MA

monomer content. With the former one, the similar result of the decrease in crys-

tallinity with the GMA graft content was observed in PCL-g-GMA polymer system

(Kim et al., 2001). This may be due to the hindrance of LLDPE crystallization by the

increase of chain structural irregularity caused by grafting reaction of GMA. In the

latter case (i-MA grafted polymer composite system), the structural regularity might

not be disturbed due to the appendage of single MA unit to the PE chain. The effects

of p-MA and i-GMA/i-MA on the crystallization behavior of polymer composites are

values of composites are reported in Figure 6. The crystallization peak also increased

around 10°C for i-MA composites and 3°C for i-GMA grafted composites. The posi-

tive change in the onset of melt crystallization, T

omc

, in presence of compatibilizer

indicate a faster crystallization process, which may be basically due to the formation

of hard phase near the surface of fibers. There was not a substantial change in the

crystallization process with the addition of compatibilizer excepting i-MA compatibil-

ized composites. The crystallization peak of 30 wt% filled SDBF/LLDPE composite

was at 107°C or T

omc

at 110.55°C as reported in literature (Kumar et al., 2010). The

p-grafted composites showed an increment in their crystallization temperature, as seen

in Figure 6 (left). This effect is basically due to the presence of the MA in the polymer

matrix and preventing the chain folding and producing changes in the form and size

of crystals (Martínez et al., 2004). The lower crystallinity index of compatibilized

composites compared to uncompatibilized composites might be giving a support to the

above mentioned fact

(Figure 5).

Figure 4.

Effect of pre-grafted polymer as a compatibilizer on the melting behavior of short delignified

bamboo fiber reinforced composites: (A) first and (B) second heating scans (

χ

c

represents crystallinity

index).

Search WWH ::

Custom Search