Information Technology Reference

In-Depth Information

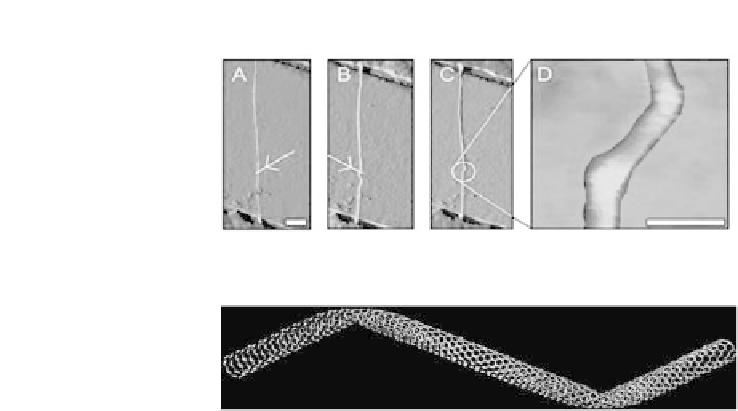

(a)

(b)

Figure

2.11.

(a) Nanotube QD fabricated by creating two kinks in the nanotube

shank using AFM manipulation. Scale bar indicates 20 nm.(From [36]. Reprinted

with permission from AAAS.) (b) Simulation of the structure Reprinted with

permission from [37] (

r

2005 American Institute of Physics)

The advantage here is that once the two nanotubes are made to cross one

another, the quantum dot is formed by the natural relaxed configuration of the

system and its size is defined automatically to be about 1.5 nm, which would be

impossible to achieve using the established patterning techniques. The effect of

this deformation on the local density of states in a similar structure was also

investigated experimentally in [39]. Thus, as can be seen, there are properties in

nanomaterials that can be capitalized on for the creation of novel devices. The

author believes that this is one of the major advantages of the world of nanoscale

devices and that many unexplored opportunities in this regard still exist.

2.4.3. Other Nanodevice Applications

2.4.3.1. Electron Emitters.

Electron emitters have long been in use in

vacuum tubes and applications such as electron microscopy and electron beam

lithography. With the advances in electron optics in these systems, the electron

emitter or source remains the performance bottleneck. Parameters such as the

brightness, energy spread, and shot noise of the electron beam directly affect

resolution, signal-to-noise ratio, and throughput in such applications. Electron

emission is the phenomenon of extracting electrons from inside a metal or

semiconductor into a vacuum. An electron emitter could be as simple as a

tungsten hairpin with a sharp point. Figure 2.13 summarizes various well

established electron emission mechanisms including emission by heating the

sample to provide the necessary kinetic energy for the electrons to overcome the

Search WWH ::

Custom Search