Information Technology Reference

In-Depth Information

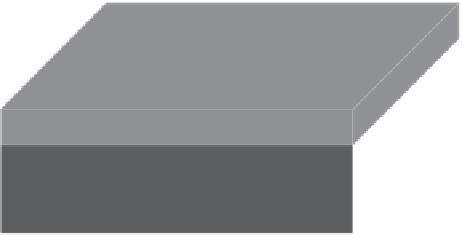

Catalyst island

Drain

Nanotube

Source (thickness: 50 nm)

Silicon dioxide (thickness: 100 nm)

Back gate

Silicon wafer

5

μ

m

Figure

2.2.

Schematic representation of a device including a nanotube attached

to two metal electrodes.

nanotube CVD is a relatively recent process that is not standard to the micro-

electronics or MEMS industry, and can be qualified exclusively as a nanofabrica-

tion step. In general, CVD leads to nanotubes growing randomly in all directions;

the task of locating the nanotubes in desired locations and orientations after CVD

can be quite time consuming and, more importantly, cannot be relied upon for

mass production of devices. It has been demonstrated, however, that the direction

of the nanotubes grown by CVD can be controlled to a large extent by the

application of an electric field [11, 12] or by using the direction of the laminar flow

of gases [13, 14] during CVD.

Just as in the case of fabrication, many of the inspection and imaging

techniques appropriate for nanotechnology have also existed for a long time.

Some of the most commonly used imaging methods with nanoscale (or even

subnanoscale) resolution include scanning and transmission electron microscopy

(SEM and TEM). These work on principles very similar to optical microscopes;

the basic difference is that instead of photons (light particles) they use electrons to

obtain an image. The reason is that electrons generated in typical laboratory

equipment can easily have associated wavelengths much smaller than photons and

thus be focused to a much smaller spot, leading to higher resolution. Another

group of techniques for imaging and manipulating nanoscale objects is scanning

probe microscopy (SPM). The idea behind these is to have a very small and sharp

tip brought in contact with a sample (although the term contact should be used

loosely in this context), scan the surface, and record the profile. Based on whether

the sample is conductive or insulating and other requirements, various types of

SPM methods can be used. Scanning tunneling microscopy (STM) and atomic

force microscopy (AFM) are two of the most popular techniques of this kind.

After a device has been fabricated and imaged, various measurements and

experiments are performed on it. There are two big challenges. The first is reaching

Search WWH ::

Custom Search