Information Technology Reference

In-Depth Information

the recording head is centered with respect to an island of the patterned SUL. In

the second case, the recording head is centered with respect to a groove between

two adjacent islands. In other words, in the second case, the head is a half-period

offset with respect to an island. The respective field profiles along same line, 5 nm

away from the surface of SUL, along a patterned direction are shown in Figure

6.11b. The fact that the field profiles are so different from each other clearly

indicates the above mentioned process of ''patterning'' the recording field. One

can observe the field in the centered case is larger (by more than a factor of two)

and substantially more localized compared to the field in the off-centered case.

This means that the head itself is going to substantially improve its recording

quality when it is recording information in the favorite positions (compared to any

off-centered positions). This is in contrast to the conventional recording process in

which the recording field profile does not depend on the location of the head with

respect to the media, regardless of whether the media being patterned or not.

Improved Localization of Recording and Sensitivity Field across the Thick-

ness: Furthermore, the effective field patterning, as described above, takes place

across the entire thickness of the recording media. In other words, the recording

and sensitivity fields could be strongly localized not only at the air bearing surface

of the head but also across the entire thickness of the recording layer. Figure 6.11c

and d illustrate the recording field profiles for the two cases of a recording system

with a patterned soft underlayer and without a SUL, respectively. In the latter

case, one could notice the great divergence of the field away from the air bearing

surface of the head. As described below, this concept can be extended to further

increase the effective number of active layers by introducing so called soft

interlayers (SIL) between adjacent layers.

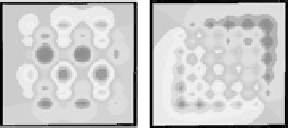

How Patterned SUL Would Help Read Across the Media Thickness: As a

simulation input, two types of information were prerecorded into the top and

bottom layers of 3D recording media with a net thickness of 50 nm (Figure 6.12a).

The ''softness'' of a patterned SUL was controlled via continous variation of

SUL's bias current, as defined above. The respective signal profiles, read back at

biasing current values of 5.85 and 1.56 A-turn, respectively, (Figure 6.12b) indeed

Parallel set of signals read back

at I

bias

= 5.85 and 1.56 (A turn)

Top layer

Bottom layer

(a)

(b)

Figure

6.12.

(a) Prerecorded magnetization in the top and bottom layers of a

20-layer recording media. (b) Sets of signals read back at a SUL's biasing current

of 5.85 and 1.56 A-turn.

Search WWH ::

Custom Search