Geology Reference

In-Depth Information

stretching force

F

to its end faces (Fig. 3.2(a)).The rele-

vant elastic modulus isYoung's modulus

E

, defined by

Elastic

field

Ductile field

Fracture

point

longitudinal stress F A

longitudinal strain

E

=

l l

D

Yield

point

Note that extension of such a rod will be accompanied

by a reduction in its diameter; that is, the rod will suffer

lateral as well as longitudinal strain.The ratio of the lateral

to the longitudinal strain is known as

Poisson's ratio

(

s

).

The

bulk modulus K

expresses the stress-strain ratio in

the case of a simple hydrostatic pressure

P

applied to a

cubic element (Fig. 3.2(b)), the resultant volume strain

being the change of volume

D

v

divided by the original

volume

v

Strain

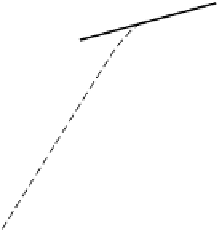

Fig. 3.1

A typical stress-strain curve for a solid body.

known as the principal axes of stress, and the normal

stresses acting in these directions are known as the

princi-

pal stresses

. Each principal stress represents a balance of

equal-magnitude but oppositely-directed force compo-

nents.The stress is said to be compressive if the forces are

directed towards each other and tensile if they are

directed away from each other.

If the principal stresses are all of equal magnitude

within a body the condition of stress is said to be

hydro-

static

, since this is the state of stress throughout a fluid

body at rest. A fluid body cannot sustain shearing stresses

(since a fluid has no shear strength), hence there cannot

be shear stresses in a body under hydrostatic stress. If the

principal stresses are unequal, shearing stresses exist

along all surfaces within the stressed body, except for the

three orthogonal planes intersecting in the principal

axes.

A body subjected to stress undergoes a change of

shape and/or size known as

strain

. Up to a certain limit-

ing value of stress, known as the

yield strength

of a ma-

terial, the strain is directly proportional to the applied

stress (Hooke's Law). This elastic strain is reversible so

that removal of stress leads to a removal of strain. If the

yield strength is exceeded the strain becomes non-linear

and partly irreversible (i.e. permanent strain results), and

this is known as plastic or ductile strain. If the stress is in-

creased still further the body fails by fracture. A typical

stress-strain curve is illustrated in Fig. 3.1.

The linear relationship between stress and strain in the

elastic field is specified for any material by its various

elas-

tic moduli

, each of which expresses the ratio of a particu-

lar type of stress to the resultant strain. Consider a rod of

original length

l

and cross-sectional area

A

which is ex-

tended by an increment

D

l

through the application of a

volume stress P

volume strain

K

=

v v

D

In a similar manner the

shear modulus

(

m

) is defined as

the ratio of shearing stress (

t

) to the resultant shear strain

tan

q

(Fig. 3.2(c))

shear stress

shear strain

tan

t

=

m

q

Finally, the

axial modulus

y

defines the ratio of longi-

tudinal stress to longitudinal strain in the case when there

is no lateral strain; that is, when the material is con-

strained to deform uniaxially (Fig. 3.2(d))

longitudinal stress F A

longitudinal strain uniaxial

y

=

)

l l

(

D

3.3 Seismic waves

Seismic waves are parcels of elastic strain energy that

propagate outwards from a seismic source such as an

earthquake or an explosion. Sources suitable for seismic

surveying usually generate short-lived wave trains,

known as pulses, that typically contain a wide range of

frequencies, as explained in Section 2.3. Except in the

immediate vicinity of the source, the strains associated

with the passage of a seismic pulse are minute and may be

assumed to be elastic. On this assumption the propaga-

tion velocities of seismic pulses are determined by the

elastic moduli and densities of the materials through