Environmental Engineering Reference

In-Depth Information

(a)

Figure 11.66

Intersection line between failure envelope and the

τ

versus

u

a

−

u

w

plane for compacted shale (data from Bishop

et al., 1960).

et al. (1960). The shale had a clay fraction of 22% and

was compacted at a water content of 18.6%. A series of

triaxial tests on saturation specimens of compacted shale

gave an effective angle of internal friction

φ

of 24.8

◦

and

an effective cohesion

c

of 15.8 kPa. The laboratory results

were reanalyzed by Fredlund et al. (1978), and the results

are presented in Fig. 11.66. The

φ

b

angle was 18.5

◦

for the

compacted shale when assuming a constant effective angle

of internal friction during the interpretation of the data.

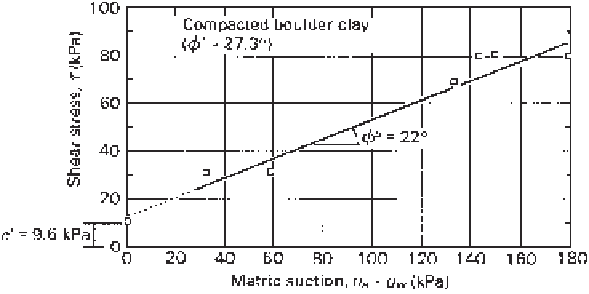

The boulder clay had a clay fraction of 18% and was

compacted at a water content of 11.6%. The saturated boul-

der clay showed an effective angle of internal friction

φ

of 27.3

◦

and an effective cohesion

c

of 7.6 kPa. The tests

on the compacted boulder clay were performed at a strain

rate of 3.5

(b)

(c)

10

-5

%/

s, and 15% strain was considered

to represent failure conditions. The laboratory results were

reanalyzed by Fredlund et al. (1978) and the results are pre-

sented in Figs. 11.67. The average

φ

b

angle was 22.0

◦

for

the boulder clay when assuming a constant effective angle

of internal friction during the interpretation of the data.

×

Figure 11.65

Stress versus strain curves and presentations of

failure envelope for Tappen-Notch Hill Silt specimen No. E-3:

(a) deviator stress versus strain curve; (b) failure envelope pro-

jected onto

τ

versus

σ

-u

a

plane; (c) line defining slope of shear

strength with respect to matric suction (from Krahn et al., 1989).

Figure 11.67

Intersection line between failure envelope and

τ

versus

u

a

−

u

w

plane for com-

pacted boulder clay (data from Bishop et al., 1960).

Search WWH ::

Custom Search