Environmental Engineering Reference

In-Depth Information

matric suction of approximately 414 kPa during the test

(Fig. 11.29b). The second test was performed under

atmospheric air pressure conditions (i.e.,

u

a

=

30

Air blew through

the disk

0). The

stress versus strain curves from both compressions tests

showed essentially the same results up to the maximum

deviator stress and only differed slightly subsequent to the

peak strengths. In other words, the measured shear strength

remained essentially unaffected by the axis translation pro-

cedure. The results also illustrate that the pore-water in the

soil was able to withstand high tensions without rupturing.

Since the soil matric suction in both tests was about 414

kPa, the pore-water pressure in the second test specimen

would be -414 kPa gauge pressure or -313 kPa in terms

of absolute pressure.

25

Aerox 'Celloton' Vl

20

15

Air blew through

the disk

Doulton

grade P6A

10

Kaolin

-consolidated

and fired

5

0

0

50

100

150

200

250

300

350

Applied matric suction (

u

a

-

u

w

), kPa

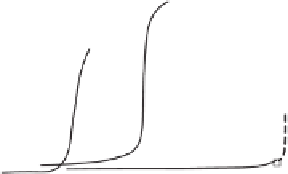

Figure 11.30

Air passage characteristics of three high-air-entry

disks (after Bishop and Henkel, 1962).

11.4.2 Pore-Water Pressure Control and/or

Measurement

Pore-water pressures in an unsaturated soil specimen can

be controlled at a prescribed value when the water phase is

maintained under drained conditions during a shear strength

test (e.g., consolidated drained test). Pore-water pressures

can be measured when the water phase is maintained in

an undrained mode throughout the test (e.g., constant water

content or in a consolidated undrained test). The key element

that provides the separation between the pore-air and pore-

water pressures is the high-air-entry ceramic disk.

The high-air-entry disk acts as a semipermeable mem-

brane that separates the air and water phases. The sepa-

ration of the air and water phases can be achieved only

when the air-entry value of the disk is greater than the

matric suction of the soil. The air-entry value of the disk

depends on the maximum size of pores in the ceramic disk.

Figure 11.30 illustrates how air commences to flow through

the ceramic disks once a limiting air-water differential pres-

sure is applied across a ceramic disk. The theoretical maxi-

mum pore size for any air-water pressure differential can be

estimated using the capillary model.

in the ceramic are controlled by the preparation and sintering

process used to manufacture the ceramic disk. The smaller

the pore sizes in a disk, the larger will be the air-entry value.

The properties of high-air-entry disks manufactured by

Soilmoisture Equipment Corporation in Santa Barbara, Cal-

ifornia, are tabulated in Table 11.2. The disks are commonly

identified by the air-entry value of the ceramic disk and

are usually expressed in the unit of bars (i.e., 1 bar

=

100 kPa). The water coefficient of permeability of a disk can

be measured by mounting the disk in a triaxial apparatus and

placing water above the disk. The disk must be sealed on

the sides (i.e., around the perimeter) in order to prevent the

passage of water around its circumference. An applied air

pressure then produces a pressure gradient across the high-

air-entry disk. The volume of water flowing through the disk

can be measured using a water volume change indicator.

Table 11.2 High-Air-Entry Disks Manufactured by

Soilmoisture Equipment Corporation

u

a

−

u

w

d

=

2

T

s

R

s

(11.31)

Range of

Air-Entry

Approximate Coefficient of

Values,

where:

u

a

−

u

a

−

u

w

d

Pore Diameter

Permeability,

u

w

d

10

−

3

mm

)

Type

(

×

k

d

(m/s)

(kPa)

=

air-entry value of the high-air-entry disk,

T

s

=

surface tension of the contractile skin or

the air-water interface (e.g.,

T

s

=

1

/

2

bar (high

flow)

10

−

7

6.0

3

.

11

×

48-62

72

.

75

mN/m at 20

◦

C), and

R

s

=

radius of curvature of the contractile skin

or the pore radius.

10

−

9

1 bar

2.1

3

.

46

×

138-207

10

−

8

1 bar (high

flow)

2.5

8

.

6

×

131-193

The air-entry value in Eq. 11.31 refers to the maximum

matric suction to which the high-air-entry disk can be sub-

jected before free air passes through the disk. The maximum

matric suction that can be sustained is associated with the

radius of the largest pore in the ceramic disk. The pore sizes

10

−

9

2 bars

1.2

1

.

73

×

241-310

10

−

9

1

.

73

×

3 bars

0.8

317-483

10

−

9

5 bars

0.5

1

.

21

×

>

550

10

−

11

15 bars

0.16

2

.

59

×

>

1520

Search WWH ::

Custom Search