Environmental Engineering Reference

In-Depth Information

30

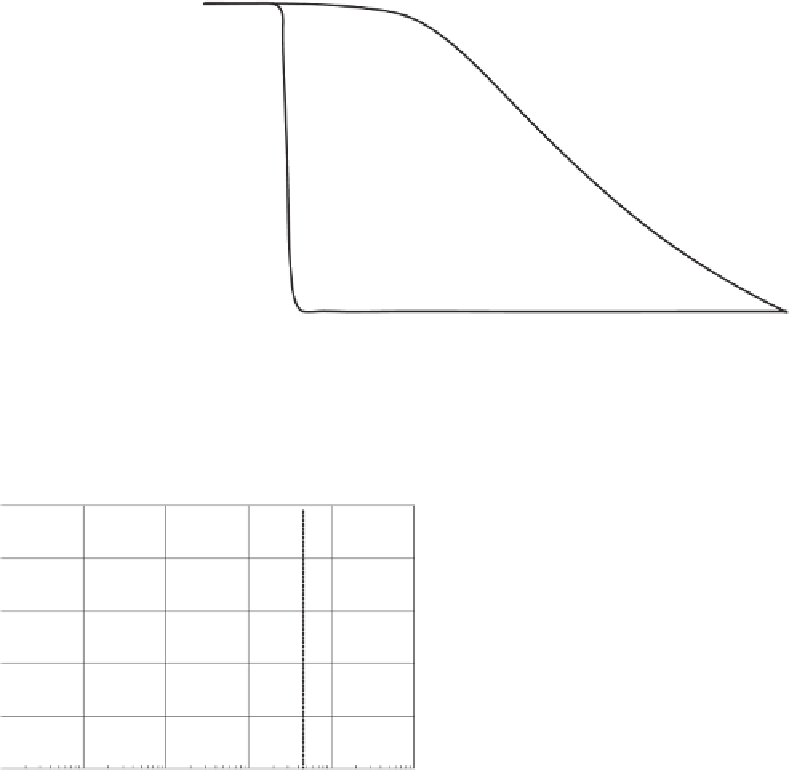

Flat curve (clay)

n

f

= 0.2,

m

f

= 1.9

20

Step curve (sand)

n

f

= 10,

m

f

= 0.8

10

0

10

6

0.1

1

10

100

1,000

10,000

100,000

Soil suction, kPa

Figure 5.101

Variation of parameters

n

f

and

m

f

according to particle-size diameter while

holding

a

f

constant at 100 kPa (from Fredlund, 1997b).

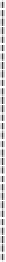

30

20

Coarse sand

Clay

10

0

10

6

0.1

1

10

100

1000

10,000

100,000

Soil suction, kPa

Figure 5.102

Assumed limits for SWCCs for uniform coarse sand (

a

f

=

1

,n

f

=

20,

m

f

=

2

,h

r

=

3000) and a clay (

a

f

=

100

,n

f

=

1

,m

f

=

0

.

5

,h

r

=

3000)

(from Fredlund,

1999b).

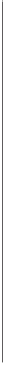

5.12.11 Designation of Porosity and Packing

Arrangement for M.D. Fredlund (2000) Model

The grain-size distribution curve can be divided into

n

frac-

tions of uniform sized particles. Each fraction has a packing

arrangement and porosity. The summation of the individ-

ual fraction porosity values may be greater than the overall

porosity of the combined soil fractions. In the assemblage of

soil particles, the voids created between larger particles will

be filled with smaller particles. Consequently, the influence

of the larger particles on the SWCC is reduced (Yazdani

et al., 2000). The porosity of the individual fractions can

be summed until the overall porosity of the soil is reached.

After this point the remaining particle fractions are ignored.

The “packing” porosity

n

p

for each uniform particle size

needs to be approximated. It can be assumed that the

n

p

100

USCS % silt

80

Experimental

Fredlund unimodal

60

USCS

% clay

Particle sizes

40

USCS

% sand

20

0

0.001

0.01

0.1

1

10

100

Particle size, mm

Figure 5.103

Small divisions of particle sizes used to build over-

all SWCC.

Search WWH ::

Custom Search