Environmental Engineering Reference

In-Depth Information

1,000,000

160

Distilled water (0 kPa) - drying

Distilled water (0 kPa) - wetting

Salt solution (9700 kPa) - drying

Salt solution (9700 kPa) - wetting

In air (70000 kPa) - drying

In air (70000 kPa) - wetting

Ridley (1995) - drying

Ridley (1995) - wetting

Harrison & Blight (1998) - drying

Harrison & Blight (1998) - wetting

Leong et al. (2002) - drying

Leong et al. (2002) - wetting

140

100,000

From solution

120

10,000

100

1,000

80

60

100

40

From suction plate, pressure plate,

and pressure membrane extractor

10

20

1

0

20

40

60

80

100

120

0

5

10

15

20

25

30

35

Filter paper water content, %

Duration, days

(a)

(a)

1,000,000

120

Distilled water (0 kPa) - drying

Distilled water (0 kPa) - wetting

Salt solution (9700 kPa) - drying

Salt solution (9700 kPa) - wetting

In air (70000 kPa) - drying

In air (70000 kPa) - wetting

McQueen & Miller (1968) - drying

McQueen & Miller (1968) - wetting

Harrison & Blight (1998) - drying

Harrison & Blight (1998) - wetting

Leong et al. (2002) - drying

Leong et al. (2002) - wetting

From solution

100,000

100

10,000

80

1,000

60

100

40

From suction plate, pressure plate,

and pressure membrane extractor

10

20

1

0

20

40

60

80

100

120

0

5

10

15

20

25

30

35

Filter paper water content, %

Duration, days

(b)

(b)

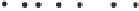

Figure 4.79

Drying and wetting processes in coming to equilib-

rium (from Rahardjo and Leong, 2006): (a) data for Whatman No.

42 filter paper; (b) data for Schleicher and Schuell No. 589 filter

paper.

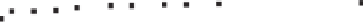

Figure 4.80

Time required for water content equilibration in fil-

ter paper (from Rahardjo and Leong, 2006): (a) equilibrium for

Whatman No. 42 filter paper; (b) equilibrium for Schleicher and

Schuell No. 589 filter paper.

Figures 4.81a and 4.81b present the equilibrium drying

and wetting water contents,

w

f

, for Whatman No. 42 and

Schleicher and Schuell No. 589 filter papers, respectively,

that were held over varying concentration salt solutions. The

equilibrium water content was taken as the water content

of the filter paper when there was no measurable change

in the weight of the filter paper with time. The hysteresis

observed was small (i.e., 1-5% in terms of the water content

of the filter paper), with the largest differences observed

for suctions less than 100 kPa. Hysteresis appeared to be

minimal when sufficient equilibration time was allowed.

Equalization Time.

Table 4.13 presents various equilibra-

tion times that have been used when making suction mea-

surements with filter paper. ASTM D5298-94 recommends

a minimum equilibration time of seven days. Two points are

important when examining the time required for the equi-

libration of the filter paper with a suction source. Time is

required for equilibration between the environment and suc-

tion source. The water vapor in the air space of a closed

container takes time to reach equilibrium. The equilibrium

time is particularly important when calibrating filter papers

using salt solutions. Time is also required for equilibration

between the filter paper and the suction source. The water

vapor in the air space must first reach equilibrium and then

the filter paper will come to equilibrium with the water vapor

in the air space.

Matric suction is applied instantly when filter paper is

calibrated using a pressure plate apparatus. The equilibra-

tion time is the time required for the filter paper to achieve

equilibrium with the applied matric suction. The filter paper

equilibration time depends on suction source, contact con-

dition, and suction level, as illustrated by the differences in

equilibration time reported in Table 4.13.

The equilibration of water vapor with the suction source

appears to be particularly important when an enclosed envi-

ronment with a soil specimen is used. Water must be lost or

gained from the soil specimen to the environment in order to

establish an equilibrium condition. A small enclosed envi-

ronment enables equilibrium conditions to be achieved more

rapidly (McQueen and Miller 1968a).

Search WWH ::

Custom Search