Environmental Engineering Reference

In-Depth Information

container should be removed to allow water to escape from

the filter paper. After drying, the container and the dry fil-

ter paper are weighed with the lid in place. The difference

between the dry and wet mass of the filter paper is used to

compute the equilibrium water content of the filter paper.

The equilibrium soil suction is obtained from the calibra-

tion curve using the measured equilibrium water content of

the filter paper. The equilibrium suction in the filter paper

is assumed to be equal to the suction in the soil specimen.

It is also possible to measure the calibration curve for

a specific filter paper by measuring the water content of

filter papers that have been equilibrated over salt solutions

having a known osmotic suction. In principle, the filter paper

calibration is similar to the calibration of psychrometers. The

filter paper should be suspended above at least 50 cm

3

of a

salt solution. The procedure for ensuring equilibration and

the measurement of water content is the same as that used

for the measurements of soil suction. Various filter paper

water contents can then be plotted against the respective

osmotic suction value to produce a calibration curve.

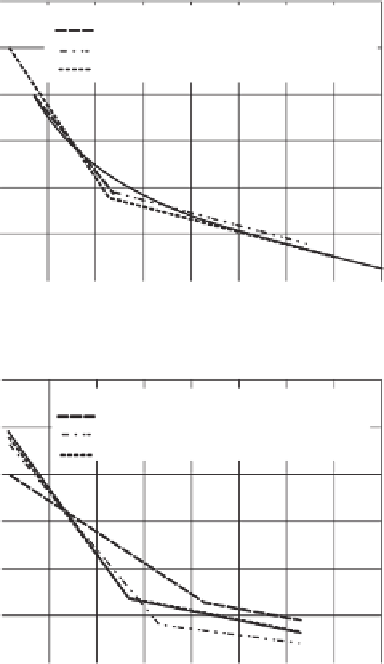

The calibration curve for filter papers exhibits a bilinear

shape, as shown in Fig. 4.75. The lower part of the curve

represents the high range of filter paper water contents where

the water is believed to be held by the influence of capillary

forces. On the other hand, the upper part of the calibration

curve represents lower water contents where the water is

believed to be held as an adsorbed water film within the

filter paper (Miller and McQueen, 1978).

The filter paper technique is highly user dependent, and

great care must be taken when measuring the water content

of the filter paper. Each dry filter paper has a mass of about

0.52 g, and at a water content of 30%, the mass of water in

the filter paper is about 0.16 g.

The above filter paper procedure is primarily based on

ASTM standard E833. Recent research on the filter paper

method (Leong et al., 2002a; Rahardjo and Leong, 2006)

has provided further insight into variations and discrepancies

that have been reported when using the filter paper method.

1,000,000

Hamblin (1981)

Chandler and Gutierrez (1986)

Chandler et al. (1992)

Greacen (1987), ASTM (D5298-94)

100,000

10,000

1,000

100

10

1

0

20

40

60

80

100

120

140

160

Filter paper water content, %

(a)

1,000,000

McQueen abd Miller (1968)

Al-Khafaf and Hanks (1974)

McKeen (1980)

Greacen (1978), ASTM (D5298-94)

100,000

10,000

1,000

100

10

1

0

20

40

60

80

100

120

140

160

Filter paper water content, %

(b)

Figure 4.76

Proposed calibration curves for various filter papers

(from Rahardjo and Leong, 2006): (a) calibration of Whatman No.

42 filter paper; (b) calibration of Schleicher and Schuell No. 589

filter paper.

is consistent in terms of its adsorptive characteristics.

Figure 4.76b shows the average calibration curves measured

on Schleicher and Schuell No. 589 in several research

studies. There appears to be slightly more variation in the

calibration curves measured on the Schleicher and Schuell

No. 589 filter paper.

The calibration curves are bilinear in character on a plot

of gravimetric water content versus the logarithm of soil

suction. The transition between the wet and dry portions of

the calibration curve occurs around a water content of about

47% for the Whatman filter paper. The transition between

the wet and dry portions of the calibration curve on the

Schleicher and Schuell No. 589 filter paper appears to range

between water contents of 54 and 85%. The change in slope

on the filter paper calibration curve appears to occur at the

residual suction point on the water retention curve.

Two equations can be written for the bilinear calibra-

tion curve for filter paper. One equation can be written for

the high-water-content range (i.e., low suction range), and

4.3.3.3 Further Details on the Calibration Technique

and Factors Affecting Calibration of Filter Paper

Leong et al. (2002a) and Rahardjo and Leong (2006) under-

took studies on the factors influencing the calibration of filter

paper for the measurement of soil suction. The calibration

curve needs to be accurately measured and needs to be repro-

ducible. Gardner (1937) suggested that improved control in

manufacturing the filter paper might result in greater accu-

racy and repeatability when using the filter paper methodol-

ogy. However, relatively consistent calibration curves have

been observed when using different batches of a particular

brand and filter paper number.

Figure 4.76a shows the average calibration curves

measured on Whatman No. 42 filter paper by a variety

of researchers. All of the calibration curves are similar,

suggesting that

the quality of the Whatman filter paper

Search WWH ::

Custom Search