Environmental Engineering Reference

In-Depth Information

measured thermal conductivity will represent the thermal

conductivity of the ceramic stone with water filling the

voids. This is an easy reading to obtain, but once again,

it is important to define how the ceramic stone has been

saturated with water. It is possible for the “wet or saturated

ceramic stone” to be immersed in water for a period of

time or placed in a back-pressured environment to ensure

that all air has been dissolved in water. Previous research

studies (Feng, 1999; Feng et al., 2002; Feng and Fredlund,

2003) have shown that simply immersing the ceramic

stones in water for a period of time does not fully saturate

the ceramic stone. Rather, occluded air bubbles become

entrapped in some voids of the ceramic stone. It was found

that back-pressuring the ceramics resulted in higher degrees

of saturation and a change in the thermal conductivity

measurement.

The complete calibration of a thermal conductivity suc-

tion sensor generally involves placing the sensors onto a

pressure-plate-type device where three to seven additional

suctions are applied to the sensor while monitoring the out-

put from the sensors. The applied suction values usually

range from 10 to 500 kPa along the desorption calibration

curve. The complete set of data points can then be best fit

using an empirical calibration equation.

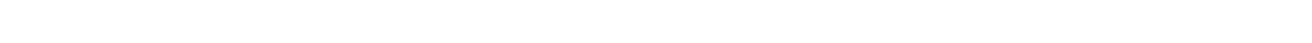

Figure 4.38 shows a typical set of calibration curve data

for the GCTS thermal conductivity (TC) suction sensors.

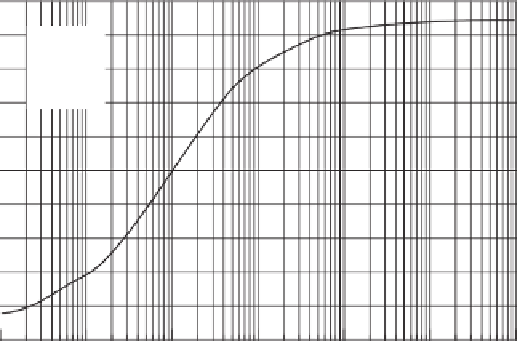

Figure 4.39 shows a typical set of calibration curve data for

the CS-229 TC suction sensors.

Hu et al. (2007) undertook the calibration of 16 GCTS

thermal conductivity suction sensors. The measured tem-

perature changes under the suction applied to each of the 16

TC suction sensors are shown in Fig. 4.40.

500

480

a

= 309.4

b

= 29.02

c

= 488.8

d

= 1.359

460

440

420

400

380

360

340

320

300

10

6

1

10

100

1000

10,000

100,000

Matric suction, kPa

Figure 4.38

Typical calibration curve for FTC-100 thermal conductivity suction sensor (man-

ufactured by GCTS, Tempe, AZ).

3.6

3.1

2.6

2.1

1.6

1.1

0.6

10

6

1

10

100

1000

10,000

100,000

Matric suction, kPa

Figure 4.39

Typical calibration curve for CS-229 thermal conductivity suction sensor (manu-

factured by Campbell Scientific 2006).

Search WWH ::

Custom Search