Biomedical Engineering Reference

In-Depth Information

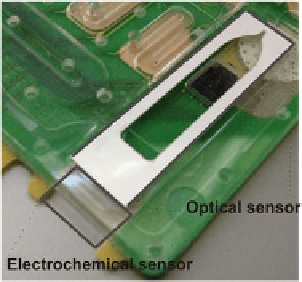

Fig. 4 Different ''free''

spaces within the cartridge

for sensor integration. Sensor

integration will be performed

via a connecting layer (in

white: protective layer)

tests cyclic olefin copolymer (COC) seemed to be appropriate due to its ability to

be formed within injection-molding processes and especially due to its low

autofluorescence. For integration into the optical sensor system the polymer film

has a size of 10 9 40 mm and a height of 0.2 mm. This film acts simultaneously

as a wave-guiding element and as the substrate for the capture molecules. To act as

a waveguide the polymer film has two integrated prisms in which laser light from a

light source within the processing unit is coupled in and out. The effect of guiding

the light into the polymer film is that an evanescent field is created which illu-

minates just a volume 100 nm next to the surface. Hence, the fluorescence signal

arising from the dye-labeled detector antibodies has a much better signal-to-noise

ratio due to a smaller background signal. In this regard, the used total internal

reflectance fluorescence-principle (TIRF) is able to deliver a higher sensitivity

compared to normal fluorescence detection. As dye-labels in general many dif-

ferent fluorescence dyes can be used. In the specific case, the use is limited to one

dye with one defined excitation wavelength of 630 nm to simplify the need of a

laser and detector within the read-out unit.

In addition to the optical read-out also an electrochemical sensor can be chosen.

In this case the substrate made in a seven-step fabrication process is an electronic

chip with a size of 8 9 10 mm having 16 gold electrodes for the immobilization of

capture molecules, a gold counter electrode, and an iridium/iridium oxide refer-

ence electrode. The electrodes have a diameter of 350 lm and capture molecules

are immobilized that are specific to the desired analyte. The concentration of the

analytes can be determined via a secondary and detection antibody which is

conjugated with an enzyme. In many cases an alkaline phosphatase or a beta-

galactosidase is used as the enzyme which converts a substrate into an electro-

chemically active substance. This can then be determined locally by measuring the

current in a three-electrode set-up. While temperature stabilization during the

binding of analytes to the capture molecules in the case of the optical sensor is

performed with a heater on the cartridge itself, the electrochemical chip has an

additional heater.

Concerning the fabrication process of both sensors the electrochemical one

seems to be much more complicated. As stated above seven fabrication steps are